History of Science and Technology in Islam

ENGINEERING in Arabic-Islamic Civilization[1]

DONALD R. HILL and AHMAD Y. al-HASSAN

Part One

INTRODUCTION

The

history of

engineering in Islam is a very wide subject indeed, and it is not easy

to do it justice in a single article.

The intention

is to present

the reader

with a fair and accurate picture of the scope and significance of Muslim

achievements in this field, and to indicate how Muslim engineers served

the needs of society and how, in a number of instances, their work was

of importance in the development of modern engineering. To realize this

intention in the space available some omissions are inevitable. In the

first place, and without entering into a lengthy discussion about the

precise meaning of the term, ‘engineering’ is taken here as a concept

that involves some degree of complexity. In civil engineering, small

structures such as dwelling houses and short-span bridges have in

general been disregarded. In the mechanical field military machines are

not discussed and devices that require the frequent and repeated use of

the human hand have been omitted. There is therefore no direct

discussion of hand tools, personal weapons or textile machinery. An

exception is made in the case of instruments – surveying and

astronomical – because of the mathematical skills required for their

construction and use.

In many cases the places and dates of origin of machines or techniques

have not been established with any certainty. It is not proposed to

devote much space to an examination of the evidence for the origin of

any particular invention, particularly if it is known that it occurred

before the advent of Islam in the first/seventh century. The estimated

time and location of origin will be given, with an indication of the

conjectural element in this estimate and the possible alternatives, if

any. It should be noted that most pre-Islamic inventions were made in

the Near East that witnessed the passage of several ruling empires from

ancient times till the advent of Islam.

Medieval Islam was a prosperous and dynamic civilization, and much of

its prosperity was due to an engineering technology that assisted in

increasing the production of raw materials and finished products. In

addition, the demand for scientific instruments, and the need to cater

for the amusements and aesthetic pleasures of the leisured classes, was

reflected in a tradition of fine technology based upon delicate

mechanisms and sensitive control mechanisms. In this paper, the

contribution of engineering to Islamic civilization will usually be

demonstrated by specific examples, since space does not allow for a

detailed survey of the interactions between technology and society.

Similarly, the Islamic contribution to the development of modern

engineering will be indicated by means of citing individual cases of

technology transfer.

CIVIL ENGINEERING

Irrigation and water

supply

For the sake of convenience it is necessary to divide the subject of

civil engineering in the Muslim world into several sections, but in fact

much of the subject is broadly contained within the field of irrigation

and water supply. Dams are used to impound and divert irrigation water,

bridges to cross canals and surveying techniques to align and level

canals and qanats. Water-raising machines, which are discussed

under mechanical engineering, are of course an integral part of

hydraulic engineering schemes. In this section, therefore, we shall

confine our attention to the principal irrigation systems, and to the

means for transporting water to the fields and to urban communities.

There are four different types of irrigation. Basin irrigation,

which was the method used in Egypt from ancient times until quite

recently, consists of levelling large plots of land adjacent to a river

or a canal, each plot being surrounded by dykes. When the water in the

river reaches a certain level the dykes are breached, allowing the water

to inundate the plots. It remains there until the fertile sediment

settles, whereupon the surplus is drained back into the watercourse.

Perennial irrigation is a method of watering crops regularly

throughout the growing season by leading the water into small channels

which form a matrix over the field. Water from the main artery – a

river, major canal or qanat – is diverted into supply canals,

then into smaller irrigation canals, and so on to the fields. Terrace

irrigation is a method used in hilly country and consists of the

formation of a series of terraces stepped down a hillside. Irrigation is

by means of stored rainfall, wells, springs and occasionally qanats.

Wadi irrigation depends upon sporadic rainstorms in otherwise arid

lands. It consists of impounding the storm water behind dams and using

this water to irrigate the fields adjacent to the watercourses. The

famous dam at Ma’rib in the Yemen was the focal point of such a system.

Following its original construction in the eighth century B.C.E. it was

successively raised, not to impound water for long periods but to raise

the wadi floods to increasingly higher levels in order to irrigate more

and more land by means of a canal system which used the wadi itself as a

drain. The final breakdown of the dam is thought to have occurred about

a quarter-century before Muhammad’s birth. From the second century

B.C.E. until the beginning of the first century C.E. the Nabateans in

southern Palestine and Jordan developed a thriving agriculture based

upon wadi irrigation. Whereas irrigation in the Yemen depended upon a

single large dam, the Nabateans built thousands of little barriers sited

across one wadi after another in order to divert or capture the one or

two weeks of runoff occurring each year.

All these methods of irrigation originated in antiquity and it cannot be

said that any radically new techniques have been added to the repertoire

of Egyptian and Mesopotamian engineers. It could scarcely be otherwise:

the basic problem of impounding the water, conducting it to the fields

and finally draining the surplus remains as it has always been.

Irrigation, and particularly perennial irrigation, however, is a branch

of civil engineering which has always demanded a high degree of

technical and administrative skills. The construction of dams, canals

and qanats, matters to do with water flow and control, and

elaborate surveying problems; all present themselves uncompromisingly

and demand the attention of experts. From one area to another, there

will always be differences in hydraulic conditions, climate, soil and

terrain, so that the engineers must apply their knowledge and experience

to produce the best system for a given set of conditions.

It is sometimes said that large cities are one of the main

characteristics of Islamic civilization, and it is of course true that

great cities such as Baghdad, Cairo and Cordoba, with their flourishing

economic, commercial and intellectual life, were a major component of

that civilization. It hardly needs emphasizing, however, that life in

these large urban centres would have been impossible without the support

of a thriving agriculture. Many Muslim cities were founded after the

advent of Islam – e.g. Baghdad, Basra and Shiraz –- and we therefore

find that the efforts of the engineers were taxed to the utmost either

in extending existing systems or in creating completely new ones.

From the

start of the Islamic Caliphate Irrigation works and water distribution

were prominent among the State’s achievements. When al-Basra was

established during Umar’s period, he started simultaneously building

some canals for conveying water and for irrigation. Two important canals

were built linking al-Basra with the Tigris River. These were al-Ubulla

River and the Ma`qil River. Basra obtained the necessary drinking water,

and the two canals were the basis for the agricultural development for

the whole Basra region.[2]

‘Umar also devised the policy of cultivating barren lands by assigning

such lands to those who undertook to cultivate them. This policy, which

continued during the Umayyad

period also, resulted in the

cultivation of large areas of barren lands through the construction of

irrigation canals by the State and by individuals.

The various governors who were appointed by the Umayyads constructed

several works to prevent the formation of new swamps and to dry old

ones, through the building of dams that regulated the flow of water. We

find in the original Arabic sources details about the irrigation works

which were constructed in Iraq and in Syria in the regions of al-Basra,

al-Kufa, Wasit, al-Bata’ih, al-Raqqa and several other areas.[3]

When the Abbasids assumed power in the second/eighth century they

followed the same policy. They expanded greatly the existing irrigation

system, mainly to cater for the needs of the new city of Baghdad, whose

population at its zenith was about 1 500 000. The network of canals

between the Euphrates and the Tigris was extended, the great Nahrawan

canal to the east of the Tigris was lengthened and two new systems on

the rivers ‘Uzaim and Diyala were added.

[4]

Although

there was some irrigation in Spain in Roman and Visigothic times, the

large systems along the River Quadalquivir and in the province of

Valencia were Muslim achievements. The rulers of al-Andalus and many of

their followers were of Syrian origin, and the climate, terrain and

hydraulic conditions in parts of southern Spain resemble those of Syria.

It is hardly surprising, therefore, that the irrigation methods –

technical and administrative – in Valencia, for example, closely

resemble the methods applied in the Ghuta of Damascus.

[5]

There were

many other irrigation systems in the Muslim world, ranging from the

great canal networks of Egypt and Iraq, down to village fields watered

from one or two wells. One of the largest systems was centred on the

city of Marw in Khurasan on the River Murghab, which provided the

irrigation water for extensive farmlands. In the fourth/tenth century

the superintendent of irrigation at Marw was said to have had more power

than the prefect of the city, and to have supervised a workforce of 10

000 men. Greatly surpassing this, however, was the land of Sughd (Bilad

al-Sughd ) – now part of

Uzbekistan.

The mainstay of its fertility was the Sughd River, now called the

Zarafshan, which flowed through the great cities of Samarkand and

Bukhara. At the height of its prosperity in the third/ninth and

fourth/tenth centuries this land was rich and fertile beyond compare,

its agriculture supported by a vast network of canals extending for many

miles around the two cities.[6]

Given the large numbers of men required to construct, maintain and

control the large irrigation systems, it is hardly surprising that most

of the enterprises were under State control, although it was not unusual

for work to be let out to subcontractors.[7]

There are several Arabic treatises which tell us a good deal about the

methods used for surveying and some of them discuss the excavation of

new canals and methods for maintaining existing ones. We shall discuss

land surveying in a separate section, but a section on quantity

surveying in a treatise written in Iraq in the fifth/eleventh century is

worth mentioning, since it also provides us with information about

irrigation works in general.[8]

Instructions are given for calculating the quantities of earth to be

excavated from canals of given lengths, widths and depths and for

converting these quantities into manpower requirements. The canal banks

were reinforced with bundles of reeds, and the man-hours required for

preparing and placing the bundles are given. For excavation, the number

of diggers (called ‘spades’) was first calculated, and to these were

added the numbers of carriers to each spade, which depended on the

distance the spoil had to be carried. Overheads for ancillary workers

and supervision were then added. There was a set price for each task, so

in the end a Bill of Quantities was produced which would provide the

estimate for the cost of the works and serve as a guide for the

recruitment of labour. Or, if the project was let out to subcontract,

the Bill of Quantities would be the main document for awarding the

contract and for the subsequent measurements and payments. Quantity

surveying methods have not therefore changed materially over the

centuries. From this treatise, and elsewhere, we get a picture of a

highly organized State enterprise, with an army of bureaucrats,

engineers and surveyors, controlling a very large labour force, whose

productivity and rates of pay were closely specified.

It is not usually easy to separate irrigation from water supply because

both systems were derived from the same hydraulic works. Thus a dam

would provide for both the town supply and the needs of the farmers,

with one main feeder channel going to the irrigation system and another

into the town. Or a canal would be led out from the main feeder canal

into the urban centre. It was collected in a reservoir inside, or just

outside, the city walls, and was conducted from there through pipes or

open channels to the baths, fountains, houses for ritual ablutions,

private and public buildings, and gardens. A particularly impressive

example of artificial storage reservoirs can still be seen just outside

the city of Qayrawan. Two large linked cisterns for receiving the waters

of the Wadi Merj al-Lil when it was in flood were completed in the year

248/862-3. Although they appear to be circular, both are actually

polygonal, the larger having a diameter of just under 130 m, the smaller

one a diameter of 37.4 m. The smaller receives the waters of the wadi

and acts as a settling tank; a circular duct several metres above its

base connects it to the larger cistern, which has a depth of about 8 m.

On leaving the larger cistern, the water is decanted a second time into

two oblong covered cisterns.[9]

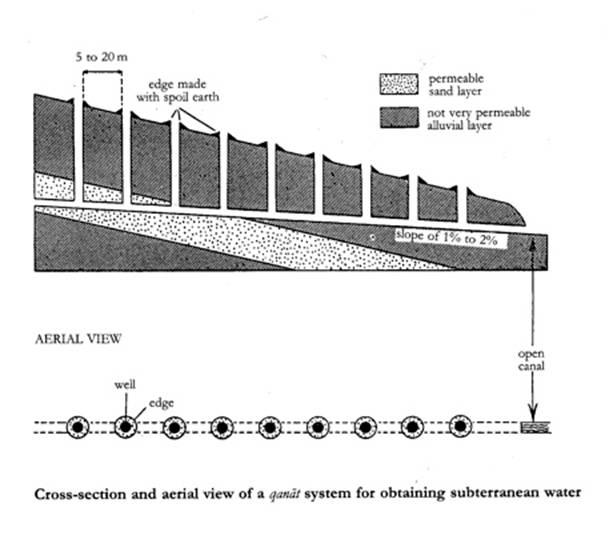

One of the most

effective methods for providing water in regions without perennial

streams is the qanat, an almost horizontal underground

conduit that conducts water from an aquifer to the place where it is

needed. The technique probably originated in northern Iran in the eighth

century B.C.E. It was in widespread use in the Muslim world in the

medieval period and up to modern times. Indeed, recent estimates have

shown that 75 per cent of all water used in Iran at the present time

comes from qanats and that their total length exceeds 100 000

miles. The city of Teheran alone has thirty-six qanats,

all originating in the foothills of the Alburz 8 to 16 miles away, with

a measured flow of 6.6 million gallons a day in spring and never below

3.3 million in the autumn.[10]

Outside Iran, qanats are still in use in parts of the Arab world,

notably in the south-east of the Arabian Peninsula and in North Africa.

The qanat system was used by the Umayyad and the Abbasid caliphs.

The Caliph Al-Mutawakkil (847-866) constructed a qanat system for the

supply of water to his new palace at Samarra. Recent excavations there

showed that the water was obtained from ground water of the upper Tigris

and conveyed to Samarra in qanat

conduits totaling 300 miles in length.[11]

Al-Karaji’s Inbat al-miyah al-khafiyya (The Bringing Out of Hidden

Waters) is a technical treatise written about 1000 C.E. which

gives good details on the finding of the water level, instruments for

surveying, construction of the conduits, their lining, protection

against decay, and their cleaning and maintenance

[12]

The construction of qanats is in the hands of experts (muqanni)

and the secrets of the profession are largely handed down by word of

mouth from father to son. The termination of the qanat,

either farmland to be irrigated or a community to be provided with

potable water, or both, will be known in advance, as will the general

location of likely aquifers. One of the main skills of the muqanni

lies in determining, by examining the alluvial fans for traces of

seepage and hardly noticeable changes in vegetation, precisely where the

trial well is to be dug. When the excavators reach the impermeable layer

the well is left for a few days while the muqanni estimates the

potential yield of the well by hoisting up measured quantities of water

and at the same time observing any fall in the water level. If

necessary, further wells are sunk to ensure that genuine groundwater has

been reached; the shaft with the highest yield is chosen as the ‘mother

well’. The next step is for the surveyor – or senior muqanni –

to determine the route, gradient and precise outlet of the qanat.

The route will be selected according to considerations of terrain

and, in some cases, questions of ownership. To start the survey, a long

rope is let down into the mother well until it touches the surface of

the water, and a mark is made on it at ground level. The surveyor then

selects a spot on the route 30 to 50 yards from the mother well for the

first ventilation shaft. A staff is held on this spot by a labourer, and

the surveyor measures the fall with a level. Nowadays a modern surveying

level may be used but in earlier times one of the instruments described

in the section below on surveying was used. A second mark is made on the

rope coinciding with the measurement on the staff; the distance from

this mark to the lower end of the rope will be the depth of the first

ventilation shaft. He continues to level in this way along the route,

marking the rope at the location of each shaft, until he reaches the end

of the rope. He has then reached a point on the ground at the same level

as the surface of the water in the mother well. For the mouth of the

qanat he now chooses a place below this level, but higher than the

fields, and divides the drop from the level point to the mouth by the

number of proposed ventilation shafts and adds this amount to the

previously surveyed depth of each shaft. In this way be determines the

gradient of the conduit, which is usually from 1 : 1000 to 1 : 500.

After completion of the survey, a number of guide shafts, about 300

yards apart, are driven under the supervision of the surveyor. Then the

rope with the marked length of each vertical shaft is handed to the

muqanni, who now begins to work with his assistants by

driving the conduit into the alluvial fan, starting at the mouth. At

first the conduit is an open channel, but it soon becomes a tunnel.

Another team sinks ventilation shafts ahead of the tunnellers, and

labourers haul the soil up to the surface through these shafts. Two oil

lamps are kept burning on the floor of the conduit; sighting along

these, the muqanni keeps the tunnel in alignment, and they also

serve as a warning of poor air, since they go out before there is a

danger of a man suffocating. As the work nears the mother well great

care has to be taken in case the muqanni misjudges the distance

and strikes the full well, in which event he might be swept away by the

sudden flow. It can be seen, therefore, that the construction of

qanats is a special example of the difficult and dangerous

profession of mining (see Figure 1). It may be considered as one of the

most successful of man’s inventions, since it has been in continuous use

for over 2500 years.[13]

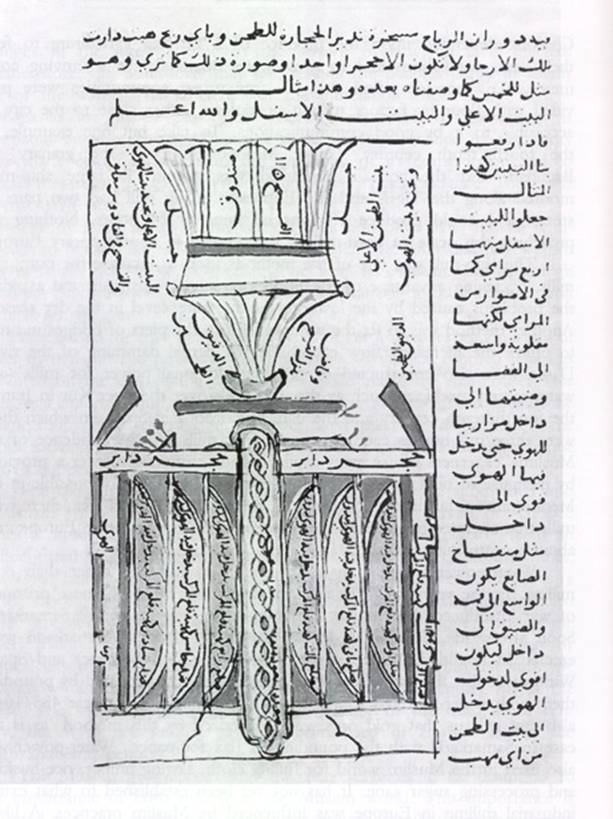

Fig. 1 –

The qanat

Dams

Dams are required in most hydraulic systems, whatever their purpose, but

the functions of dams vary. In wadi irrigation, as we have seen, they

are used to trap the floodwaters that result from heavy but infrequent

downpours, so that the water-level is raised above that of the

surrounding fields, to which it can then be conducted under gravity. For

perennial irrigation dams are used to divert water from streams or

rivers into the canal network. The impounding of rivers behind dams

gives more control over the supply throughout the year. As with wadi

irrigation, it also allows the water in the reservoir to be gravity-fed

into irrigation and town supply systems. A further advantage, if the

water is to be used for hydro-power, is that there is a high, fairly

constant head of water, which would not be the case if the river were

unregulated.

There are two basic types of dam – gravity and arch. The first, as its

name implies, relies upon the weight of the dam to withstand the

pressure of the water. For additional strength, buttresses are sometimes

added to the downstream wall. As with all hydraulic structures, good

foundations are of the utmost importance, since failure can occur if the

scouring action of the water undermines the foundations. Arch dams are

designed to resist the force of the water and silt by horizontal arch

action and are adaptable only to those sites where the length is small

in comparison to the height and the sides of the valley are composed of

good rock to resist the arch thrust at the haunches. With very rare

exceptions true arch dams were not built before modern times.

The selection of the materials of construction was influenced partly by

the design of the dam and partly by availability. Earth dams were common

and are still in widespread use today. They are perfectly satisfactory

for certain kinds of service, provided they have a core of clay or other

impermeable material and plenty of overflow capacity, but they are not

really suitable for high dams. In certain areas, notably lower Iraq,

earth dams were almost universal; they were (and are) quite adequate for

diverting rivers into canal systems and, in any case, the cost of

transporting large quantities of stone would have been prohibitive. In

other areas, where higher dams were needed, some form of masonry

construction was necessary. This could be of dressed stone, mortared or

not, random rubble or concrete. Quite frequently, dams were constructed

by building two masonry walls with a gap between them, and then filling

the gap with cheaper material such as earth or rubble. If the dam was

designed to discharge overflow water from its crest, this had to be of

stone or concrete, since earth would quickly have been worn away by the

action of the water.

Roman and Sasanid dams were carefully maintained, but the demands for

irrigation water and power was so great that in the more populous

provinces dams became more numerous than they had been in pre-Islamic

times. Many new dams were necessary as part of the extensions to the

hydraulic systems in Iraq.

Perhaps the most impressive of these dams, the remains of which can

still be seen, was a diversion dam over the River ‘Uzaym at the point

where it leaves the hills called the Jabal Harmin. The main body of the

dam is a masonry wall 575 feet long which at the western end turns

through a right angle and continues for 180 feet to form one bank of the

canal called Nahr al-Batt. The dam has a maximum height of something

over 50 feet, but this rapidly reduces towards the sides. In fact for

the first 150 feet at the eastern end, the dam is only 13 feet high. The

cross-section of its central portion has a neat trapezoidal profile, 10

feet thick at the crest and 50 feet thick at the base. The water face is

vertical and the air face is built to a uniform slope with the masonry

stepped. The dam was built of cut masonry blocks throughout, connected

with lead dowels poured into grooves. This is quite a common Muslim

technique and in the ‘Uzaym dam was apparently used as a complete

alternative to mortared joints. The alignment of the structure is not

straight, and this reflects an attempt, as usual, to utilize the natural

shape of the site as advantageously as possible.[14]

In Iran the Muslims added dams to the existing Sasanid systems. A new

dam called the Pul-i Bulaiti was built at Shustar on the River Karun,

the main purpose of which was to provide power for milling. The mills

were installed in tunnels cut through the rock at each side of the

channel, with the dam providing the necessary head of water. Another

example is the bridge-dam at Dizful which was used to power a great

water-wheel working a mechanism which raised water 50 cubits and

supplied all the houses of the town.

[15]

The Buwayhids held the real power in Iraq and Iran from 320/932 until

454/1062, and the greatest builder of the dynasty was ‘Adud al-Dawla.

Among his works was the impressive dam called the Band-i Amir, built

about 349/960 over the River Kurr in the province of Fars between Shiraz

and Istakhr. This dam was seen by the geographer al-Muqaddasi shortly

after it was constructed. He speaks of it as follows:

‘Adud al-Dawla closed the river between Shiraz and Istakhr by a great

wall, strengthened with lead. And the water behind it rose and formed a

lake. Upon it on the two sides were ten water-wheels, like those we

mentioned in Khuzistan, and below each wheel was a mill, and it is today

one of the wonders of Fars. Then he built a city. The water flowed

through channels and irrigated 300 villages.[16]

This dam, which is some 30 feet high and 250 feet long still survives.

It is made of solid masonry and does make use of a rubble masonry core.

Iron bars set in lead were used to connect the blocks. Both Al-Muqaddasi

and Ibn al-Balkhi agree that the stones were set in mortar, and this, in

addition to binding the whole construction together, would also have

served to make the dam watertight. The use of “tempered cement and

sifted sand” indicates that the engineers were aware of the need for

careful preparation of their mortar. Al-Balkhi writes ”even an iron tool

could not scratch it” This indicates that the mortar was of excellent

quality and that the dam was a very thorough and solid piece of work. It

is not at all surprising that it has had such a long and useful life.[17]

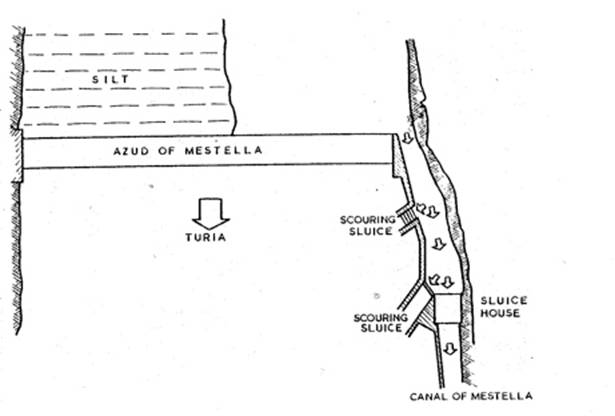

There are many Muslim dams in Spain, a large number of which were built during the fourth/tenth century, the golden age of Umayyad power in the peninsula. In this period, for example, many small dams, or azuds, were built on the 150-mile-long River Turia, which flows into the Mediterranean at Valencia. (In passing it is important to note the Spanish word azud, from Arabic al-sadd, one of very many modern irrigation terms taken directly from Arabic and certain proof of Muslim influence on Spanish technology.) Eight of these dams are spread over six miles of river in Valencia, and serve the local irrigation system. Some of the canals carry water much further, particularly to the Valencian rice fields. These, of course, were established by the Muslims, and continue to be one of the most important rice-producing centres in Europe. All eight dams are similar in construction, being fairly low with vertical water faces and stepped air faces. The cores consist of rubble masonry and mortar, and the structures are faced with large masonry blocks with mortared joints. Sluices in the outflow canals permitted surplus water to drain back into the river during normal operation, and occasionally they would be opened to their full extent in order to de - silt the approaches to the canal mouth. Such scouring sluices are absolutely essential to prevent the silt which collects behind a dam from choking the canal intakes and the canals themselves (see Figure 2). The foundations of these dams are massive; the masonry of the structure extends some 15 feet into the river bed and is supported on rows of wooden piles. These relatively massive foundations for low dams are accounted for by the fact that there are occasional dangerous floods in which the flow of the Turia is increased a hundredfold. The dams are then submerged to a depth of nearly 20 feet and must resist the battering of water, stones, rocks and trees. Because they are so low and flat and are provided with deep and very firm foundations, the Turia dams have been able to survive these conditions for 1000 years.[18]

Fig 2 –

Mestella dam: desilting sluices

Not the least of the problems facing the builders of dams is that the

energy of the water spilling over the crest of a dam can, over the

years, undermine the foundations on the downstream side. A satisfactory

solution to this problem is demonstrated by a Muslim dam near Murcia on

the River Segura. The air face of the dam had a large surface area, and

this was put to good use. Water flowing over the crest initially fell

vertically through a height of 13-17 feet on to a level platform, 26

feet wide, running the length of the dam. This served to dissipate the

energy of the water spilling over the crest. The overflow then ran to

the foot of the dam over flat or gently sloping sections of the face. In

this way the whole dam acted as a spillway and the energy gained by the

water in falling 25 feet was thereby dissipated, so greatly reducing the

risk of undermining the downstream foundations. From this example – and

many others could be cited – it is evident that the Muslims had a good

empirical understanding of hydraulics.[19]

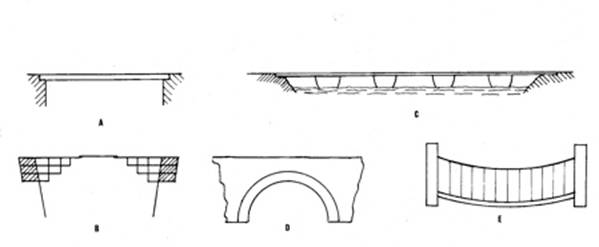

Bridges

Suspension bridges with cables made of woven bamboo strips were used in

China no later than the first century B.C.E. but there is no record, of

its use in western Islam or Europe before the Renaissance. This does not

mean that they were not used and indeed it would be strange if this

simple and effective method of crossing ravines was unknown in the

Zagros, the Taurus and the mountainous regions of Spain and North

Africa. Similarly, we have no firm evidence for the use of cantilever

bridges in Islam, apart from Afghanistan, where they had been built

from, at the latest, the fifth century C.E. onwards. These are also an

excellent method of crossing ravines in hilly country, but being made of

timber they do not have a long life nor do they leave traces,

particularly since in many cases modern bridges may have been built at

their sites. Usually a timber substructure is built into a masonry

abutment on either bank, and the longitudinal and transverse beams to

carry the roadway extend from the top of this supporting structure. At

the centre the two cantilever spans support a short beam section (see

Figure 3). Large modern steel bridges, such as the Forth railway bridge

in Scotland, are built on exactly the same principle. In the

fourth/tenth century a bridge over the River Tab in Iran was described

briefly by Ibn Hawqal. He says that the river was crossed by a wooden

bridge “suspended between the sky and the water, its height above the

water about 10 cubits”. He may, of course, have seen a suspension

bridge, but the cantilever type seems more likely, especially since he

makes no mention of ropes.

Fig. 3

–Types of bridges

There are frequent references to pontoon bridges in the works of Arabic

writers. They were very common in Iraq for crossing the two rivers and

the major irrigation canals. In the fourth/tenth century there were two

pontoon bridges over the Tigris at Baghdad, but only one was in use; the

other, having fallen into disrepair, was closed, because few people used

it. Ibn Jubayr, writing towards the close of the sixth/twelfth century,

described a bridge of large boats over the Euphrates at Hilla. It had

chains on either side “like twisted rods” which were secured to wooden

anchorages on the banks. He also mentions a similar, but larger, bridge

over a canal near Baghdad. There were also pontoon bridges on the rivers

of Khuzistan, the Iranian province adjoining Iraq, and on the Helmand

river in Sijistan (now western Afghanistan). There seems to have been a

pontoon bridge at Fustat (now Old Cairo) in Egypt for many years. In the

early part of the fourth/tenth century, al-Istakhri says that one bridge

crossed from the city to the island and a second bridge from the island

to the far bank of the river. About two centuries later, al-Idrisi

describes the same arrangement, adding that there were thirty boats in

the first bridge and sixty in the second.

Before the introduction of modern materials the masonry arch provided

the best solution for the spanning of watercourses and other obstacles.

Although they are relatively expensive to build, well-constructed arch

bridges can last for centuries and they do not interfere with river

traffic to the same extent as pontoon bridges or the many piers of

multiple-span beam bridges. Their durability is proved by the survival

of many medieval bridges, intended only for the passage of people and

animals, but now sustaining the full load of modern traffic.

Many Roman, Hellenistic and Sasanid arch bridges remained in use in the

Muslim world, and the more impressive of these are described in the

writings of the Arabic geographers. The Muslims, following the

traditions of their predecessors, also built many fine arch bridges. In

areas where good building stone was not available, notably in parts of

Iran, the bridges were built from burnt bricks, but most of them were

constructed from cut stone. The geographer al-Qazwini (d. 682/1283) has

left us a graphic description of a great arch bridge at the town of

Idhaj in Khuzistan; it spanned a ravine that was normally dry, but in

times of flood became a turbulent lake. It was re-built by the Wazir of

Rukn al-Dawla al-Hasan b. Buwayh (d. 366/977) who conscripted craftsmen

from Idhaj and Isfahan. The bridge was 150 cubits (dhira’) in

height and consisted of a single arch, strengthened with lead dowels and

iron clamps. The slag from iron workings was used to fill the space

between the arch and the roadway[20].

Another remarkable bridge, over the River Tab in Iran, was seen by

al-Istakhri in the early part of the fourth/tenth century. He says that

it was built by an Iranian, physician to the Umayyad governor al-Hajjaj

(d. 95/714). It was a single arch of span about eighty paces and so high

that a man on a camel with a long standard in his raised hand could pass

beneath it. An unusual bridge was among the works of Ibn Tulun governor

of Egypt from 254/868 to 270/884. A high causeway of 6 miles was

constructed from the Nile at Fustat towards the west and the bridge,

consisting of forty great arches, was an extension to the causeway. The

purpose of these works was to provide a passage for the army over the

Nile floods if an enemy approached from the west. There were many arch

bridges over canals in all the Muslim provinces where irrigation was

practiced.

Building construction

Many fine buildings were constructed in the first Islamic century: the

Dome of the Rock in Jerusalem, the Great Mosque in Damascus, the second

Great Mosques in Kufa and Basra and the desert palaces of the Umayyads –

to name only some of the more notable buildings. Once established, the

tradition for fine architecture continued to flourish in Islam, as

witnessed, for example, by al-Mansur’s Baghdad, the works of Ibn Tulun

in Egypt, the Great Mosque of Cordoba and the Alhambra palace in

Granada, the complex of splendid buildings in Isfahan and so on. Many

well-illustrated books have been devoted to describing Islamic buildings

and it is clearly beyond the scope of this chapter to attempt even a

brief summary of the Muslim architectural achievement. Instead, we shall

confine our attention to the most basic element in any building – the

materials of construction.

The Muslim geographers usually tell us which type of material was used

to construct a given town or city. This could be unfired bricks (labin

or tub), fired bricks (ajurr), stone (hajar)

or timber. In medieval times timber was more plentiful than it is

today, but even so the practice of constructing the main structures of

buildings in this material was not widespread. The city of Bukhara was

mostly timber-built and the houses in the town of Siraf on the Gulf were

made of teak, and timber was also widely used in parts of Spain. Perhaps

the most important example of timber used as a structural material is

the Dome of the Rock in Jerusalem, in which the dome itself consists of

two independent wooden shells, the outer one covered with lead sheets.

In general, however, timber was used in conjunction with other materials

where some resistance to tensile stresses was necessary, as in lintels

over doors and windows, and roof rafters.

The choice of material to be used in a particular building depends upon

a number of factors: the availability of a material locally, cost, time

and the purpose of the building. Thus it is noticeable that cut masonry

was often preferred for religious buildings whereas other large

buildings in the same region might be constructed from cheaper

materials. Syria can be said to be the region, par excellence,

for fine stonework in ashlar masonry, i.e. masonry in which each

block is carefully cut to size, with straight edges and plane surfaces.

This tradition has persisted in Syria to the present day; the local

limestone weathers to a beautiful amber colour that is very pleasing to

the eye. Ashlar work was also common in Spain (doubtless due to Syrian

influence), Egypt and parts of North Africa. Sometimes money and time

were saved by building the wall in random rubble and facing it with

ashlar. The mortar was based upon either lime or gypsum mixed with soft

sand.

The use of unfired bricks was common in early Antiquity and is still

widespread today. The clay which is the main constituent of the bricks

is readily available in many parts of the world and houses made from

this material are warm in winter and cool in summer. Moreover, its use

is not confined to the building of small dwelling houses. Some of the

multi-storey houses in southern Arabia are made of unfired bricks, and

they can also be used in vaults and domes. They cannot, however, be used

in areas with high rainfall, for heavy rains cause severe deterioration

to the walls to the point of making them disintegrate. The labina

generally has a geometric, fairly regular shape, that of a

parallel-sided rectangle, whose variable dimensions often have the ratio

4 x 2 x 1 (e.g. length 56 cm, width 28, thickness 14, or 36 x 18 x 9)

but in South Arabia 45 x 35 x 5 is usual and in Iran 20 x 20 x 4. To

prepare the mixture for the bricks, the loam or clay is thoroughly

soaked, mixed with straw and chaff and trodden with the bare feet. It is

then carried in baskets to the moulders. Each moulder has a wooden

mould, just an open frame. He covers the ground with a thin layer of

chaff, puts the moulding frame flat on the ground, throws a quantity of

the mud-straw mix into the mould, beats it into the corners with his

bare hands, and scrapes off any surplus with a small straight-edge. He

lifts the frame with a swift movement, leaving the fresh brick on the

ground, and places the frame next to the brick just made. Moulding row

after row in this way, he makes about 250 bricks in an hour. Unfired

bricks are jointed with a mortar made with a mixture of lime or ash and

are usually lined with a coating of earth mixed with lime or plaster.

Burnt bricks were already made in the fourth millenium B.C.E in

Babylonia and in Iran. kilns have been unearthed going back into the

first millenium B.C.E. They are still in common use in many parts of the

Muslim world. They are generally smaller than unfired bricks, and the

preparation of the clay for them is more thorough – it has to be slaked

and sieved to clean it of impurities, and additives are sometimes

included, e.g. grey sand to give the bricks a whitish tinge. After

moulding they are left in the open, lying fiat, for 24 hours, and then

turned on edge and left to dry for another three days before being

stacked in the kiln. The kiln is similar to that of the potters, and

consists of a furnace with a firing room on top of it. Buildings made

exclusively from burnt bricks are rare. More usually they are combined

with other materials. The Qasr al-Hayr al-Gharbi in Syria, for example,

built in the first Islamic century, consists of a wall of limestone,

fired bricks and unfired bricks at the top. Burnt bricks were (and are)

used for certain parts of buildings such as arches, vaults and

staircases, and put to good use by architects to vary the decoration of

their works. From the sixth/twelfth century, the glazed brick has

offered the possibility of obtaining similar effects to those of mosaic.

The technique of cobwork (tabya) was described in detail

by Ibn Khaldun in his Muqaddima, which implies that he

thought it a characteristically Muslim practice. Earth with which chalk

and crushed baked earth or broken stones are often mixed is rammed

between two boards kept parallel by beams.[21]

The wall is plastered over, often in such a way as to simulate joints of

heavy bond-work beneath. When this plaster falls, the regularly spaced

holes left by the beams become visible. In the Muslim West cobwork

became general in the fifth/eleventh and sixth/twelfth centuries,

especially in military building. In the Maghrib it seems to have been an

importation from Andalusia, where it had long been known.

In urban communities, quality control of building was exercised by an

official called the muhtasib. His duties were very wide-ranging,

since he was appointed by the ruler to supervise the affairs of the

market, including the maintenance of moral standards and religious

observance; quality and quantity control over retailers and

manufacturers; sanitation and water supply; and checking the manufacture

of building materials. In this last respect the hisba manuals

(books written for the guidance of the muhtasib) contain a good

deal of useful information. For example, the widths of walls and the

dimensions of beams were checked with wooden templates, to ensure that

the measurements were not less than the minimum specified.[22]

Surveying

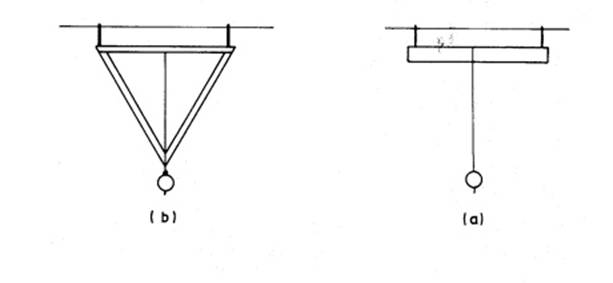

The basic requirements for public works surveying, as in the setting-out of large buildings, the excavation of canals, etc. are levelling and alignment. Whereas nowadays levelling is done with an optical instrument and a graduated staff, in earlier times two such staffs were needed in conjunction with a simple but effective instrument. Three such instruments are described in an Iraqi treatise of the fifth/eleventh century[23]. The first of these is a wooden board about 70 cm long by 8 cm wide. In the centre of the board a line is drawn which meets both edges at a right angle. A plumb line is fixed to this line, near one of the edges. Two hooks are fixed to this edge (see Figure 4a). The second instrument consists of an equilateral triangle, with two hooks soldered to the ends of one of its sides. A narrow hole is drilled through the centre of this side, to take the cord of a plumb line (Figure 4b). To use either instrument, it was suspended to a wire or cord stretched tightly between the two graduated staffs. One end of the wire was moved up and down until the plumb line coincided with the line on the board or the corner of the triangle. The difference between the readings on the two staffs gave the level difference. The third instrument is called the ‘reed-level’. A narrow longitudinal hole is bored through a long straight reed, and a radial hole is made into this bore at the centre. The reed was held roughly horizontally by two assistants between the two staffs, which were held vertically by two other assistants. A fifth assistant then allowed water to drip into the central hole from a piece of rag. When the flow of water from each end of the reed was equal the reed was truly horizontal. As with the first two instruments, the surveyor then read and recorded the heights on the two staffs. Quite accurate levelling could be carried out over long distances by repeating the operation with any of these instruments. At the end of the survey the ‘rises’ and ‘falls’ were totalled and the difference between the totals gave the difference in level between the start and finish points.

Fig. 4

For setting out straight lines and for measuring distances ropes were

used, with knots at intervals to mark the dimensions. A rotatable

alidade, provided with sighting holes and mounted on a plane surface,

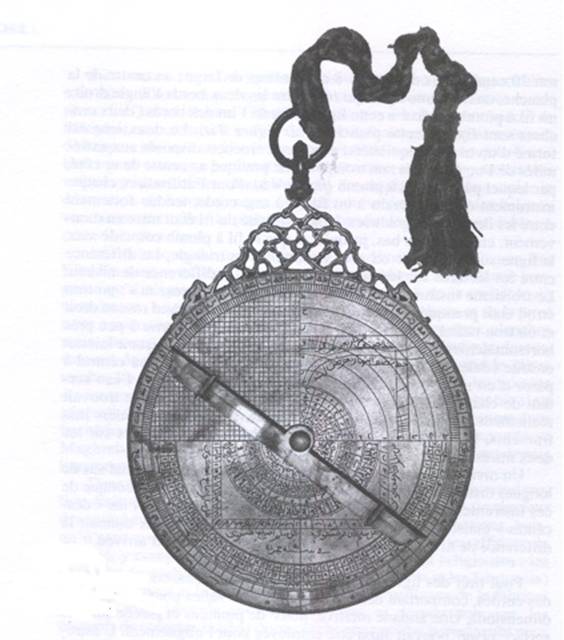

could also be used for alignment. The astrolabe, which we shall meet in

a later section as an instrument for astronomical observation and

computation, was also widely used for land surveying. Here we are

concerned only with the back of the instrument, which consisted of an

alidade turning about a central pivot, its ends moving over a graduated

circle, each quadrant of which was divided into 90 degrees. In the lower

half of the face was a rectangle, one side of which was divided radially

into decimals, the other side into duo-decimals (see Figure 5).

Fig. 5

The instrument was used for alignment and measuring the angles between

two points, but a number of Arabic writers also describe the solution of

various triangulation problems using the astrolabe. The two matching

squares into which the rectangle is divided are used for this purpose.

Although the squares are divided into ten and twelve equal parts

respectively, the choice of number is purely a matter of convenience.

With the astrolabe freely suspended the alidade is adjusted so that a

distant object is viewed through the sights simultaneously. When this

happens the real right-angled triangle formed by the distance of the

object and its height is reproduced on a small scale within the confines

of one square on the astrolabe, by an exactly similar right-angled

triangle. The real and similar triangles have a common line for

hypotenuse. The ratio of the lengths of the sides of the triangle on the

astrolabe is the same as the ratio of the height and distance of the

object, so that if either of these is known the other may readily be

calculated. If neither is known, the observer reads the angle from one

station, moves back a measured distance, and again reads the angle.

Since the Muslims had perfected the methods of both plane and spherical

trigonometry, problems of this sort could easily be solved. For the

surveyor in the field, however, it was clearly preferable to use the

constructive methods provided by the astrolabe, and manuals for his use

were prepared by scientists. Other problems solved by the use of the

astrolabe included finding the width of a river, or the distance between

two points separated by an impassable obstruction.

Part Two

MECHANICAL

ENGINEERING

Water-raising

machines

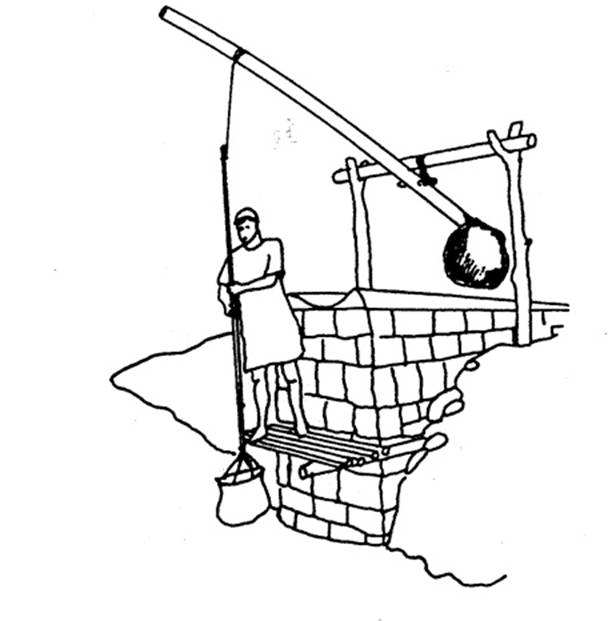

The earliest machine used by man for irrigation and water supply is the

shaduf. It is illustrated as early as 2500 B.C.E in Akkadian

reliefs and about 2000 B.C.E. in Egypt. It has remained in use until the

present day and its application is world-wide, so that it is one of the

most successful machines ever invented. Its success is probably due to

its simplicity, since it can easily be constructed by the village

carpenter using local materials. For fairly low lifts it delivers

substantial quantities of water. It consists of a long wooden pole

suspended at a fulcrum to a wooden beam supported by columns of wood,

stone or brick. At the end of the short arm of the lever is a

counterweight made of stone or, in alluvial areas where stone is not

available, of clay. The bucket is suspended to the other end by a rope

(see Figure 6). The operator lowers the bucket into the water and allows

it to fill. It is then raised by the action or the counterweight and its

contents are discharged into an irrigation ditch or a head tank.

Fig.

6

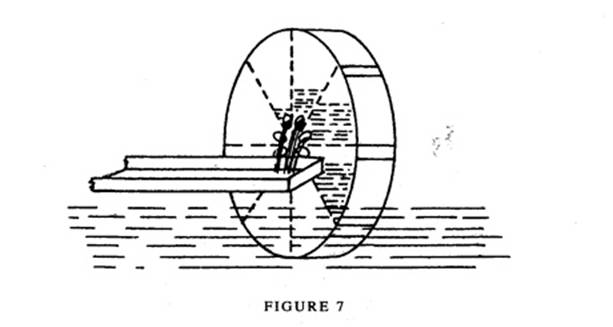

The scoop drum or tympanum was probably invented in Egypt in the

first half of the third century B.C.E. Two large timber discs were fixed

to a wooden axle which had iron pegs protruding from its ends. The pegs

were housed in iron bearings supported on two columns. The space between

the discs was divided into eight segments by wooden boards. The

perimeter was closed by wooden boards, there being a slot in each

segment to receive the water. Circular holes were cut around the axle in

one face of the drum, one hole to each segment. The whole machine was

coated with tar (see Figure 7). As the drum was rotated by a

tread-wheel, the water was scooped from the source, entered the

compartments when they were at the bottom of their travel and was

discharged from them when they approached the top. The water ran into a

channel and then into a head tank. The scoop drum is rarely mentioned by

Muslim writers in connection with irrigation, and its main use seems to

have been in de-watering mines. It is ideally suited for this purpose

since it can be operated in a fairly restricted space. It was necessary

to use a series of drums: the first raised the water into a tank on a

platform, a second wheel raised it from this tank to a second tank and

so on, until the water was discharged into a drain at the head of the

mine.

Fig 7

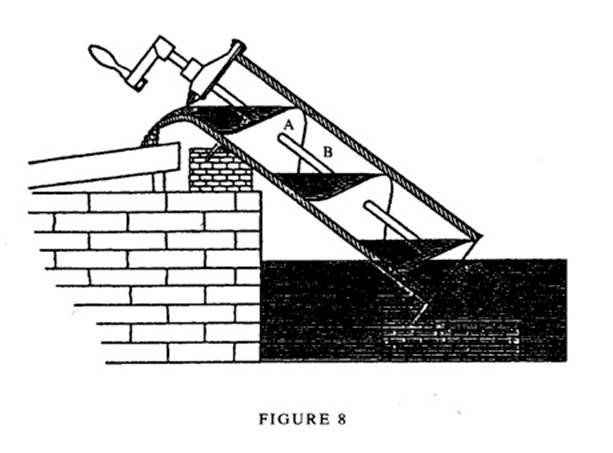

The screw or water-snail was probably invented by Archimedes (c.

287-212 B.C.E.) when he was living in Egypt and it is therefore

appropriate that the machine is often called the ‘Archimedean screw’. A

wooden blade is fitted spirally to a long cylindrical wooden rotor. A

wooden case is made to fit around the blade, constructed like a barrel,

the planks painted with pitch and bound with iron hoops. The rotor is

supplied with iron spigots which rotate in iron journals. The screw is

set at an angle with one of its ends in the water and as it is rotated

the water flows along the helix and discharges from the other end. The

smaller the angle to the horizontal, the greater will be the rate of

discharge. We do not know precisely how the machine was turned in

earlier times – it may have been by a tread-wheel, the power transmitted

through a pair of gears. Nowadays it is usually operated by a crank, but

the crank is not known to have been in use before the sixth/twelfth

century. The screw was in common use throughout the Muslim world until

quite recently, but now seems to be becoming rarer (see Figure 8).

Fig 8

The word saqiya is used here to denote the chain-of-pots driven

through a pair of gear-wheels by one or two animals harnessed to a

draw-bar and walking around a circular track. This very important

machine was invented in Egypt, probably about 200 B.C.E., but did not

come into widespread use until the fourth or fifth century C.E., with

the introduction of the pawl mechanism and earthenware pots. Although it

is fairly easy to explain the operation of the machine, it should be

emphasized that its construction is quite complex, consisting as it does

of over 200 separate components. Only the basic constructional details

will be given here. The draw-bar to which the animal is harnessed passes

through a hole in an upright shaft to which the horizontal gear -wheel

is fixed by spokes. The shaft rotates in a thrust bearing at ground

level and another bearing above the gear -wheel located in a cross-beam

which is supported on plinths. The gear-wheel is a lantern-pinion, i.e.

two large wooden discs held apart by equally spaced pegs. The vertical

gear- wheel carries the chain-of-pots and is often called the potgarland

wheel. It is supported centrally over the well or other source of water

on a wooden axle. On one side of it are the pegs that enter the spaces

between the pegs of the lantern-pinion and these pegs pass through to

the other side of the wheel, where they carry the chain-of-pots. This

consists of two continuous loops of rope between which the earthenware

pots are attached – sometimes chains and metal containers are used

(Figure 9). In order to prevent the wheel from going into reverse, the

machine is provided with a pawl mechanism, which acts on the cogs of the

potgarland wheel. This mechanism is essential, because the draught

animal is subjected to a constant pull both when moving and when

standing still. The pawl is activated in two cases – when the animal is

to be unharnessed and in the event of the harness or traces breaking.

Without the pawl the machine would turn backwards at great speed and,

after one revolution, the drawbar would hit the animal on the head. At

the same time, many of the pins of the lantern - pinion would break and

the pots smash.

Fig. 9 –

A saqiya at Ma’arrat al-Nu’man near Aleppo, Syria

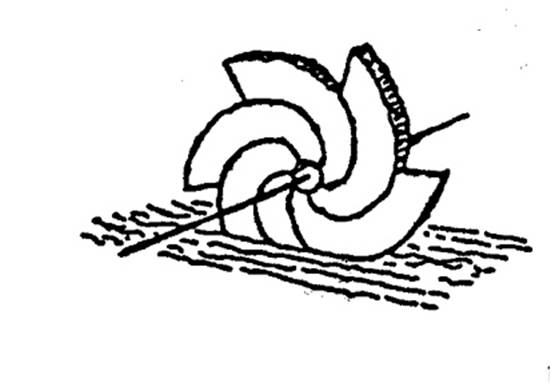

As the animal walks in a circular path, the lantern-pinion is turned and this rotates the potgarland wheel. The pots dip into the water in continuous succession and discharge at the top of the wheel into a channel connected to a head tank. Although the main function of the saqiya is for irrigation it can also be important for water supply when, for example, buildings are some distance above the source of water. The longer the chain-of-pots, i.e. the lift, the lower the rate of discharge will be. For domestic water supply this may not be a crucial factor, but in fact one of the problems of water-raising engineering is that of raising large quantities of water through a small lift. The problem can be solved by using a spiral scoop-wheel (see Figure 10), which raises water to ground level with a high degree of efficiency. This machine is very popular in Egypt nowadays, and engineers at a research station near Cairo have been trying to improve the shape of the scoop in order to achieve maximum output. Although it appears very modern in design, this is not the case, since a miniature from Baghdad dated to the sixth/twelfth century shows a spiral scoop-wheel driven by two oxen. The transmission of power is the same as that employed with the standard saqiya.

Fig. 10

The saqiya was widely used in the Muslim world from the earliest

days onwards. It was introduced to the Iberian peninsula by the Muslims,

where it was massively exploited. Not only was it diffused into many

parts of Europe but it was also taken to the New World by Christian

Spanish engineers. It has advantages over the diesel-driven pump: it can

be constructed and maintained by local craftsmen and does not require

the importation of fuel. The long history of the saqiya is by no

means ended, and there are welcome indications that its advantages will

ensure its survival for the foreseeable future.

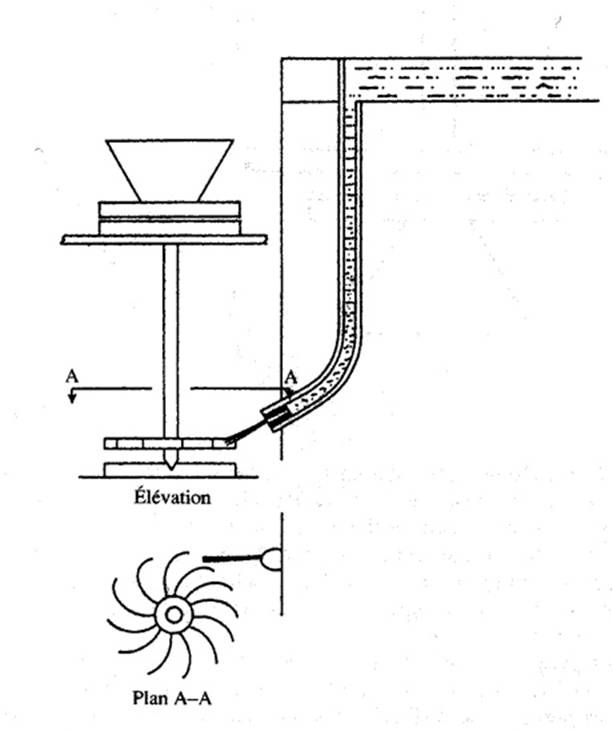

The noria is also a very significant machine in the history of

engineering. It consists of a large wheel made of timber and provided

with paddles. The rim of the wheel, inside the paddles, is divided into

compartments or, in another type of noria, earthenware pots

similar to those of the saqiya, are lashed to the rim. The wheel

is mounted on an axle over a running stream, so positioned that the

paddles and the compartments, at the lowest part of their travel, are

immersed in the water. The force of the current acting on the paddles

causes the wheel to rotate, the compartments fill with water and

discharge their contents when they reach the top of the wheel. The water

usually collects in a head tank and is then conducted through a feeder

channel to the irrigation system or to an urban water supply (see Figure

11). Being driven by water, the noria is self-acting and requires

the presence of neither man nor animal for its operation.

Fig. 11 –

Noria at Hama, Syria

The earliest description we have of the noria occurs in the

writings of Vitruvius in the first century B.C.E., in words that imply

that it had already been in use for some time. It was invented around

200 B.C.E. in the Near East. Its use was widespread in the Muslim world,

wherever conditions were appropriate; there are attestations for its use

in Iraq, Iran, Mesopotamia, Spain and elsewhere. The most famous

norias are those at Hama, on the River Orontes in Syria. These are

an impressive sight, the largest being over 20 metres in diameter; they

discharge into the end of an aqueduct that carries the water to the town

and the fields. These machines are known to have been in operation since

the third/ninth century, but there were probably norias at this

site much earlier than this. The large-scale use of norias was

introduced to Spain by Syrian engineers. An installation similar to that

at Hama was in operation at Toledo in the sixth/twelfth century and the

machine was heavily exploited all over Muslim Spain. It was diffused to

other parts of Europe and to East Asia, and like the saqiya has

shown remarkable powers of survival into modern times.

Five water-raising machines are described in al-Jazari’s great book on

machines, composed in Diyar Bakr in 602/1206. One of these is a

water-driven saqiya, a type of machine that is known to have been

in everyday use in medieval Islam. Three of the others are modifications

to the shaduf, obviously intended to raise the output of the

traditional machine. These are important for the ideas they embody,

ideas which are of importance in the development of mechanical

engineering. In one of them, for example, the concept of minimising

intermittent working is implied and another incorporates a crank, the

first known example of a crank used as an integral part of a machine.

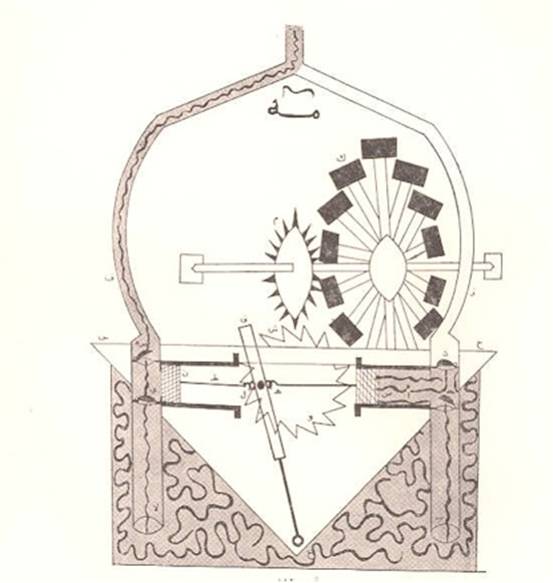

The fifth machine is the most significant. This is a water-driven

twin-cylinder pump (Figure 12). A paddle wheel is mounted on a

horizontal axle over a running stream, with a gear-wheel mounted on the

other end of the axle. This meshes with a horizontal gear-wheel

installed in a large triangular wooden box which is mounted over a pond

supplied from the stream. On the face of the second gear-wheel, near the

outside, is a peg which enters a slot-rod pivoted at one corner of the

box. The connecting rods were fixed to the sides of the slot-rod by

staple-and-ring fittings. On the end of each connecting rod was a

piston, consisting of two copper discs with a space of about 6 cm

between them, the space filled by coiling hempen cord until the gap was

filled. The cylinders, made of copper, were provided with suction and

delivery pipes, all provided with non-return clack-valves. The two

delivery pipes were joined together above the machine to form a single

delivery pipe, which discharged the water at a height of about 14 m

above the level of the stream. The action was as follows: when the

paddle wheel turned it caused the gear-wheel on its axle to turn, and

this rotated the gear-wheel in the box and the peg made the slot-rod

oscillate from side to side. When one piston was on its delivery stroke

the other was on its suction stroke. The important features embodied in

this pump are the double-acting principle, the conversion of rotary into

reciprocating motion, and the use of true suction pipes. The hand-driven

pumps of classical and Hellenistic times had vertical cylinders which

stood directly in the water which entered them through plate-valves in

the bottoms of the cylinders on the suction strokes. The pumps could

not, therefore, be positioned above the water level. A quarter-scale

working model of this pump was made for the 1976 World of Islam Festival

in the Science Museum, London. The construction is the same as that of

the machine described by al-Jazari, except that the drive was electric.

The pump works perfectly, with smooth transmission and the discharge of

a steady stream of water from the delivery pipe.

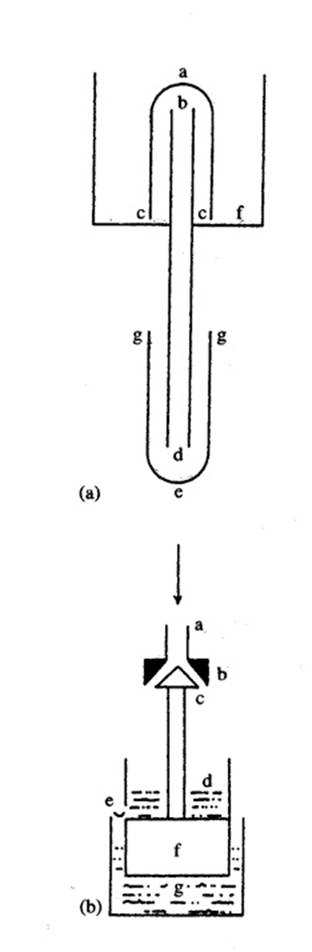

Fig 12

-Al-Jazari’s two cylinder suction pump

Evidence for the continuation of a tradition of mechanical engineering

is provided by a book on machines written by Taqi al-Din about the year

959/1552. A number of machines are described, including a pump similar

to al-Jazari’s, but the most interesting device is a six-cylinder

‘Monobloc’ pump. The cylinders are bored in line in a block of wood

which stands in the water – one-way valves admit water into each

cylinder on the suction stroke. The delivery pipes, each of which is

also provided with a one-way clack-valve, are led out from the side of

each cylinder and brought together into a single delivery outlet. On the

end of each piston rod is a lead weight, and a trip lever is connected

by a pin joint to the piston rod just below the weight. Cams on the axle

of a water-driven scoop-wheel bear down on the trip levers in succession

raising the pistons for the suction stroke. When the trip lever is

released the weight forces the piston down for the delivery stroke (see

Figure 13). It is worthy of note that Taqi al-Din’s book antedates the

famous book on machines written by Agostino Ramelli in 1588. It is

therefore quite possible that there was some Islamic influence on

European machine technology even as late as the tenth/sixteenth century.[24]

Fig. 13 – Taqi al-Din’s six cylinder pump

Power

from water and wind

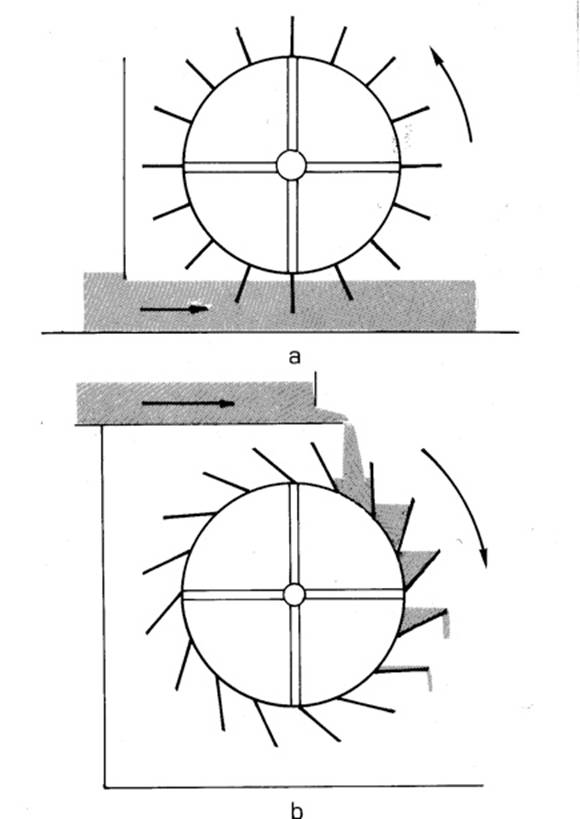

There are three basic types of water-wheel, all of which had been in use

for centuries before the advent of Islam and the question of their

origin, and diffusion, which is still unresolved and controversial, need

not concern us here. The first – the undershot wheel – is a paddle wheel

mounted on a horizontal axle over a running stream (Figure 14a). Its

power derives almost entirely from the velocity of the water, and it is

therefore affected by seasonal changes in the rate of flow of the stream

over which it is erected. Furthermore, the water level may fall, leaving

the paddles partly or totally out of the water. The efficiency of the

undershot wheel is not high perhaps as low as 22 per cent – because so

much of the energy is dissipated by turbulence and drag. The fact that

it retained its popularity over many centuries is due to the simplicity

of its construction and to special measures that can be taken to

increase its performance. These will be discussed later.

The overshot wheel is also vertical on a horizontal axle. Its rim is

divided into bucket-like compartments into which the water discharges

from above, usually from an artificial channel or ‘leat’ (see Figure

14b). Its efficiency can be as high as 66 per cent, provided all the

water from the leat falls into the buckets and there is no spillage.

Fig 14 a

and b

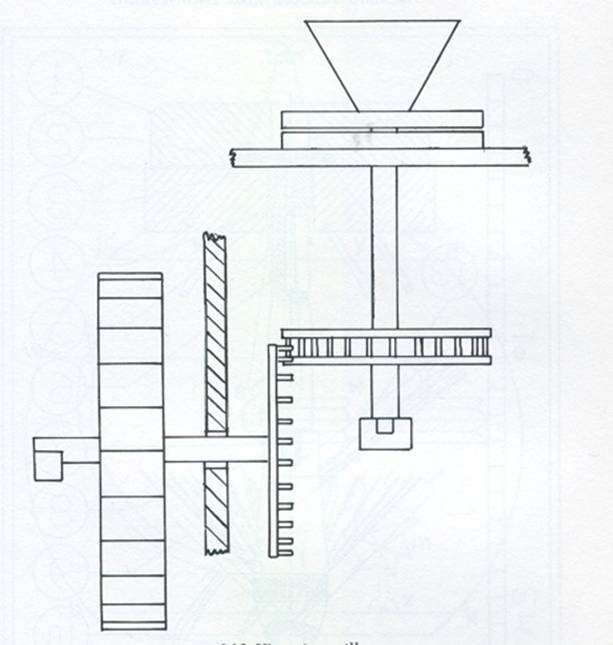

When used for corn milling, both types of vertical wheels require a pair

of gears to transmit the power to the millstones. A vertical toothed

wheel is mounted on the end of the water-wheel’s axle inside the mill

house. This engages a lantern-pinion, whose vertical axle goes up

through the floor to the milling room; it passes through the lower,

fixed millstone and is fixed to the upper, rotating stone. The corn is

fed into the concavity of the upper stone from a hopper (see Figure 15).

Fig. 15

The third type of wheel is horizontal, and can be subdivided into two

main types. In the first of these a wheel with curved or scooped vanes

is mounted at the bottom of the vertical shaft and water from an orifice

fitted to the bottom of a water tower is directed on to the vanes, the

flow being therefore tangential and radial (Figure 16). The second type

is a vaned wheel, also fixed to the lower end of a vertical axle, and

installed inside a cylinder into which the water cascades from above,

turning the wheel mainly by axial flow. Axial-flow wheels can also be

driven by vertical jets of water directed on to them from below. The

first sub-type was known in Europe and western Asia by the sixth century

C.E. at the latest. The second appears in an Arabic treatise of the

third/ninth century, but is not known to have been used in Europe before

the tenth/sixteenth century.

Fig. 16

The Muslim geographers and travellers leave us in no doubt as to the

importance of corn-milling in the Muslim world. This importance is

reflected not only in the widespread occurrence of mills, from the

Iberian peninsula to Iran, but also in the very positive attitude of the

writers to the potential of streams for conversion to power. The Tigris

at its source, says al-Muqaddasi, would turn only one mill, and

al-Istakhri looking at a fast-flowing stream in the Iranian province of

Kerman, estimates that it would turn twenty mills. It is as if these

travellers were rating streams at so much ‘mill-power’. This concern is

understandable when we remember that the great cities of Islam such as

Baghdad, Fustat and Cordoba depended upon the produce of a thriving

agriculture to feed their large populations and to provide the finished

materials for a thriving commerce. We therefore find that all large

urban communities were provided with flour by factory milling

installations, either close to the city or accessible to it by good

communications. To take but one example: in the fourth/tenth century

Upper Mesopotamia was the granary for Baghdad and the corn it produced

was ground in large ship-mills moored on the Tigris and the Euphrates.

Each mill had two pairs of stones and could produce 10 tonnes of flour

in 24 hours. Nothing approaching this scale of corn-milling was known in

contemporary Europe.

The

ship-mill was one of the methods used to increase the output of mills,

taking advantage of the faster current in midstream and avoiding the

problems caused by the lowering of the water level in the dry season.

Another method was to fix the water-wheels to the piers of bridges in

order to utilize the increased flow caused by the partial damming of the

river. Dams were also constructed to provide additional power for mills

(and water-raising machines) such as the dam built by ‘Adud al-Dawla

over the River Kur in Iran. In the sixth/twelfth century al-Idrisi

described the dam at Cordoba in Spain, in which there were three mill

houses each containing four mills. Until quite recently its three mill

houses still functioned, but have changed a lot from their original

form. Further evidence of the Muslims’ eagerness to harness every

available source of water power is provided by their use of tidal mills.

This application is, of course, not possible in the Mediterranean, but

in the fourth/tenth century in the Basra area there were mills that were

operated by the ebb-tide. Tidal mills did not appear in Europe until

about a century after this.

Water power was also used in Islam for other industrial purposes.. It

seems that the use of water power in industrial applications was already

established at an early date. Jabir Ibn Hayyan (b.721- d.815 C.E.) in

Kitab al-Sab’in (Book of the Seventy) describes in treatise

XVIII a spherical vessel for melting metals. This sphere was erected on

a river and it was rotated by a water wheel. The sphere rotated

continuously while it was heated by fire from underneath it.[25]

Jabir describes a similar continuous rotating motion on a river in

treatise XXXIV of the same book.[26]

In the year 134/751, after the battle of Atlakh or Talas, Chinese

prisoners of war introduced the industry of paper-making in the city of

Samarkand. The paper was made from linen, flax or hemp rags. Soon

afterwards paper mills on the pattern of those in Samarkand were erected

in Baghdad, the Yemen, Egypt, Syria, Iran, North Africa and Spain.

Without doubt, the raw materials in these mills were prepared by

pounding them with water-powered trip-hammers. Writing about the year

435/1044, al-Biruni tells us that gold ores were pulverized by this

method “as is the case in Samarkand with the pounding of flax for

paper”. Water power was also used in the Muslim world for fulling cloth,

sawing timber and processing sugarcane. (It is interesting to note that

the transfer of technology between China and Islam was a two-way

traffic; according to Marco Polo, the Muslims taught the Chinese how to

refine sugar.) It has not yet been established to what extent industrial

milling in Europe was influenced by Muslim practices. A likely area of

transfer is the Iberian Peninsula, where the Christians took over, in

working order, many Muslim installations, including the paper mills at

Jativa.

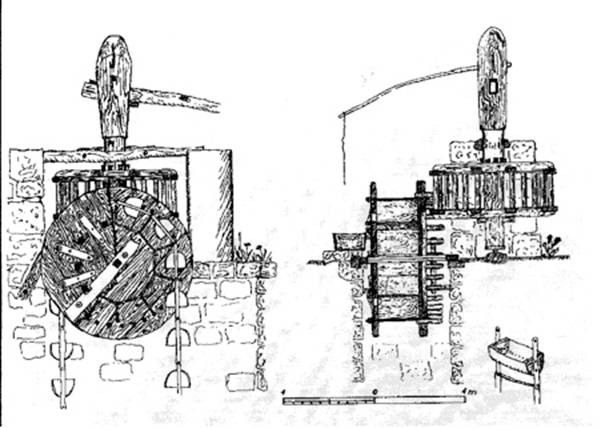

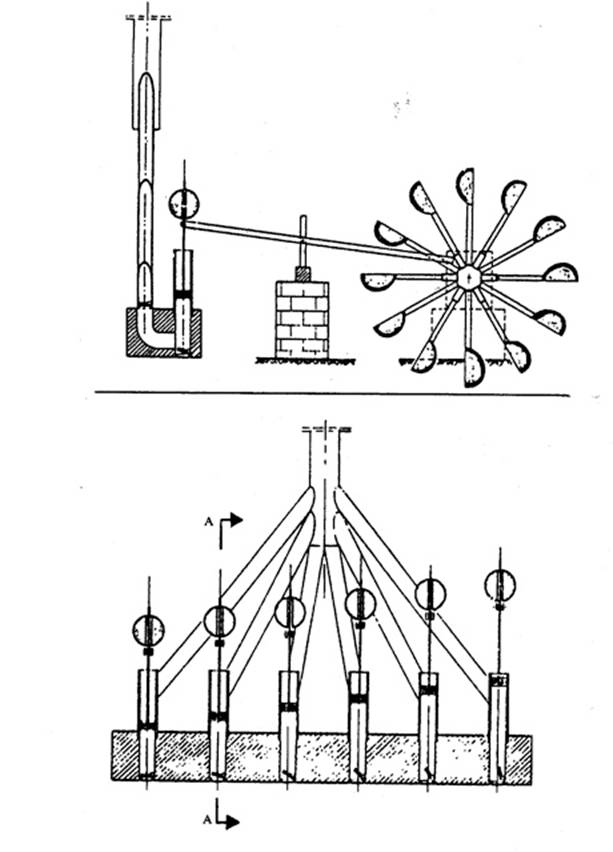

Windmills were probably known in Seistan (the western part of modern Afghanistan) before the advent of Islam. According to al-Mas’udi, a Persian claimed to the Caliph ‘Umar I that he was able to build a windmill. ‘Umar made him substantiate his claim by building one. Mills in Seistan are mentioned by the Arab geographers of the fourth/tenth century, but the first full description occurs in a book written about the year 669/1271[27]. These were not the European type of windmill with a horizontal axle and a pair of gears. The mills were supported on substructures built for the purpose, or on the towers of castles or on the tops of hills. They consisted of an upper chamber in which the millstones were housed and a lower one for the rotor. The axle was vertical and it carried twelve or six arms covered with sails. The walls of the lower chamber were pierced with funnel-shaped ducts, with the narrower end towards the interior in order to increase the speed of the wind when it flowed on to the sails (Fig. 17). This type of windmill spread throughout Islam, and to China and India. In medieval Egypt it was used in the sugar-cane industry, but its main application was to corn-milling.

Fig. 17 – Wind mill in Seistan as described by al-Dimashqi

FINE TECHNOLOGY

The expression ‘fine technology’, applied to earlier times, embraces a

whole range of devices and machines, with a multiplicity of purposes:

water clocks, fountains, toys and automata and astronomical instruments.

Some were designed to tell the time, as aids to scientific investigation

and some to delight and amuse. What they have in common is the

considerable degree of engineering skill required for their manufacture,

and the use of delicate mechanisms and sensitive control systems. Many

of the ideas employed in the construction of ingenious devices were

useful in the later development of mechanical technology.

When we look into the origins of fine technology, we inevitably find our

attention directed to the Hellenistic world and, in particular,

Alexandria. Thus we find that the first complex water clock and the

first musical automaton are both attributed by Vitruvius to Ctesibius,

an Egyptian engineer who worked in Alexandria about 250 B.C.E, and the

first major treatise on ingenious devices was composed by Philon of

Byzantium a contemporary of Ctesibius. Philon’s work was continued and

extended by Heron of Alexandria, who flourished in the middle of the

first century C.E. The origins of the astrolabe can be firmly placed in

the school of Alexandria. It was almost certainly known to Ptolemy and

was described by Theon of Alexandria (c. 350 C.E.), whose writings are

preserved in the treatise of Severus Sebokht, who composed his book in

Kinnesrin in the north of Syria before 660 C.E. i.e. a few years after

the Arab rule..

The tradition of fine technology continued uninterrupted and was further

developed under Islam. Monumental water clocks in Syria continued to be

installed in public places. The Abbasid Caliphs were interested in

clocks and ingenious devices. The story of the clock that was presented

by Harun al-Rashid (786-809), to

Charlemagne in 807 C.E. is well known.[28]

It is reported also by Ibn Abi Usaybi’a that Al-Mutawakkil (d. 861) was

so obsessed with ingenuous devices, literally Alat mutaharrika

(moving machines), that he favoured the Bani Musa who took advantage of

the Caliph’s obsession and persecuted their opponents..[29]

The Banu Musa wrote their book on al-Hiyal during this period,

and we infer from this story that they had actually constructed and

operated their devices to please and satisfy the Caliph. In Kitab

al-hayawan, al-Jahiz (776-867 C.E.) when discussing the

measurement of time, says: ” Our kings and scientists use the astrolabe

by day and the binkamat (clocks) by night”[30]

It is reported also by historians that Nasir al Dawla of Diyar

Bakr (d. 1061 C.E.) had constructed a public binkm (clock) for

the city of Mayyafariqin in the year 1012 C.E.[31]

When al-Jazari wrote his book 200 hundred years later in Diyar

Bakr, he was describing a tradition that was firmly established in that

area. Other clocks in public places were installed in some other cities

of the Islamic east.

The technology of clock-making was transferred to

Muslim Spain and to Al-Maghrib. About the year 1050 C.E. al-Zarqali

constructed a large water clock on the banks of the Tagus at Toledo in

Spain. The clock was still in operation when the Christians occupied

Toledo in 1085 C.E. A manuscript describing Andalusian monumental clocks

was written in the eleventh century by Ibn Khalaf al-Muradi.

[32] Water clocks were constructed

for public places in al-Maghrib. The remains of a public water clock in

Fas can still be seen.[33]

In Damascus, Muúammad al-Khurasani al-Sa’ati (the

clockmaker) built a monumental clock around 1160. The clock was

described by several travellers, It was still in operation when Ibn

Batuta visited Damascus in the 14th century.[34]

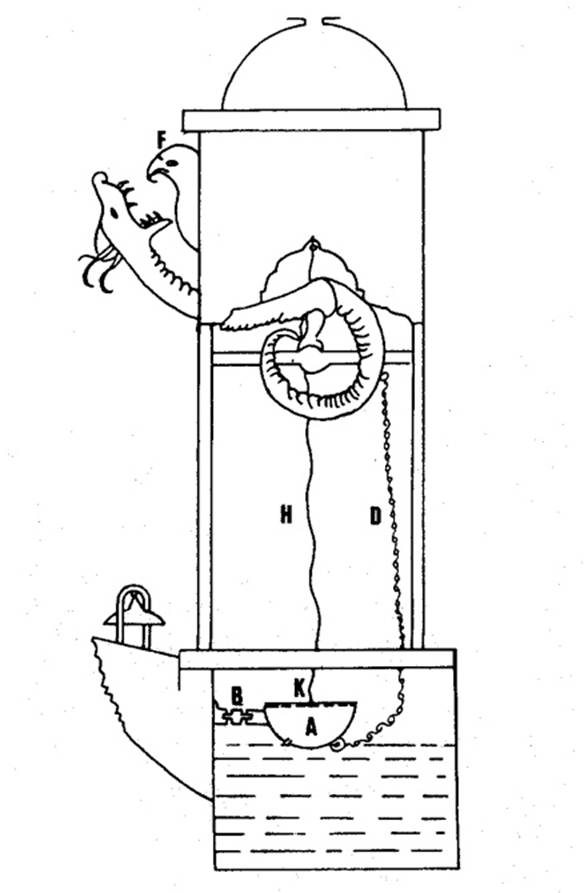

Ridwan al-Sa’ati, the son of the clock’s maker, re-built the clock and

gave a detailed description of its construction in 1203.

Al-Jazari’s book was written in Amid, Diyar Bakr, in 1206. This

book together with Kitab al-hiyal of Bani Musa, are the most

important treatises on fine technology that came down to us. It is

reported also that the astronomer ‘Ali al-Qushji (d. 1474) wrote a

tadhkira or treatise on spiritual machines[35].

The last important writer on the same subject was Taqi al-Din ibn Ma’ruf

al-Dimashqi who wrote a book on water clocks in 1552 and another on

mechanical clocks in 1556.

[36]

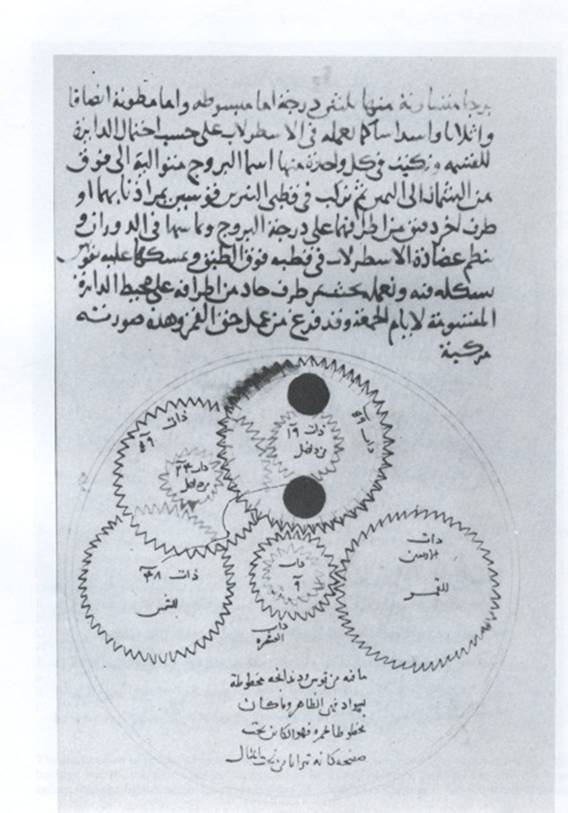

In addition to water clocks and ingenious devices, the

making of astrolabes and of geared astronomical mechanisms in Islam

continued throughout the centuries as will be shown later. Our knowledge

of Islamic fine technology will continue to improve with the publication

of more research results.

It is not easy in the space available to demonstrate

the achievements of Muslim engineers in the field of fine technology.

This can probably best be done by considering a few of the more

important Islamic works, placing emphasis upon their innovative

features. The Banu Musa were three brothers – Muhammad, Ahmad and

al-Hasan – who were members of the courtly circles of the Abbasid Caliph

al-Ma’mun (198/813-218/833) and his successors. This was the period that

witnessed the first flowering of Arabic science, both in the translation

of Greek and Syriac works into Arabic and in original scientific and

technological works, and much of this activity was carried out under the

direction and patronage of the Banu Musa. They were also scientists and

engineers in their own right and wrote about twenty treatises, only two