History of Science and Technology in Islam

The Origin of Damascus Steel In Arabic Sources[1]

1. Introduction

The main function of this paper is to make available to historians generally a selected number of passages in Arabic medieval literature (some of which were hitherto unpublished) which bear upon ferrous technology. There are other numerous sources which are not cited here. Thus, this paper is not exhaustive in this respect. For each source, an English translation is presented followed by the Arabic text.

Thus, Section 2 below quotes al-Kindi on the location of steel centers, and Section 3 gives al-Biruni's description of Damascene crucible steel production. The following section from al-Jildaki describes what seems to be the production of pig iron and cast steel, and so on.

The review of sources concludes with Section 8. No attempt is made to draw general conclusions, except that the evidence adduced seems ample to demolish the commonly held notion that Damascene steel was produced only or mainly from Indian wootz steel, or that Damascus was not a center for producing steel. Section 8 locates iron mines in the Damascus region, and documents the persistence of the ferrous industry there down to modern times.

2. AI-Kindi on Sources and Centers of Production

Among the extant works of Abu Yusuf b. lshaq al-Kindi (fI. 850), "the philosopher of the Arabs", is "A Treatise (Addressed) to some of His Brethren Concerning Swords" رسالة إلى بعض إخوانه في السيوف The treatise contains much useful technological information. But we shall be content in this paper to give al-Kindi's classification of the various kinds of iron and steel from which swords were being made. The passages below have been excerpted from this treatise [2]

Natural and not-natural iron:

“Learn that iron from which swords are forged is divided into two primary or main divisions: natural (as mined) and not-natural (i. e. manufactured). Natural iron is divided into two divisions: shaburqan شابورقان and it is the male, hard iron which can be heat-treated قابل للسقي by its nature, and narmahin (narm-ahin), which is the female soft iron which cannot be heat-treated by its nature. [Swords] can be forged from either of these two kinds or from both combined. Thus, aIl kinds of swords made of natural iron fall into three kinds: shaburqani, narmahani, and those made of a combination of both.”

اعلم أن الحديد الذي تطبع منه السيوف ينقسم قسمين أولين: إلى المعدني والذي ليس بمعدني، والمعدني ينقسم قسمين: إلى الشابورقان وهو المذكر الصلب القابل للسقي بطباعه، والى النرماهن وهو المؤنث الرخو الذي ليس بقابل للسقي بطباعه ، وقد يطبع من كل واحد من هذا الحديد مفردا ومنهما معا مركبين. فجميع أنواع السيوف المعدنية ثلاثة الشابورقانية والنرماهنية والمركبة منهما.

Not-natural or manufactured iron or steel:

"Iron which is not natural (i.e. manufactured) is steel or fuladh فولاذ . 1t means the refined or purified المصفّى. It is made of natural iron by adding to it while smelting sorne (ingredients) for purifying it, and for decreasing its softness, until it becomes strong, flexible, susceptible to heat treatment, and until its firind فرند appears.” [3]

فأما الحديد الذي ليس بمعدني فهو الفولاذ ومعناه المصفا ، ويصنع من المعدني بأن يلقى عليه في السبك شيء يصفيه ويشد رخاوته حتى يصير متينا لدنا يقبل السقي ويظهر فيه فرنده.

Three main qualities of steel:

“This steel is divided into three divisions: the antiqueالعتيق, the modem المحدث , and the non-antique, non-modern. Swords may be forged from all these steels. Thus, there are three kinds of swords: the antique, the modern, and the non-antique, non-modern.”

وهذا الفولاذ ينقسم إلى ثلاثة أقسام إلى العتيق والمحدث والى لا عتيق ولا محدث وقد يطبع من هذه جميعا السيوف. فانواع السيوف الفولاذية ثلاثة: عتيق ومحدث ولا عتيق ولا محدث.

"Antique" means top quality steel:

" Antique is not related to time (or age) but it indicates the noble or the generous qualities, as when it is said "an antique horse" meaning a noble horse (of good breed). That (sword) which has the noble qualities is "antique", no matter in which age it was forged. At the extreme end of the "antique" is its opposite in meaning, I mean that (sword) which is deprived of the qualities of the "antique". That is why it was given an opposite name, i. e. modern, even if was forged before the time of `Ad [4]. Those (swords) which have sorne qualities of the "antique", but which are deprived of sorne of its qualities, are the swords which exhibit sorne of the qualities of the "modern". Therefore, these swords are given a name in the middle between both, and they are classified as non-antique, non-modem even if they are forged in ancient or modern times. Sword- makers called some of these swords "non-antique", and called some others "non-modern".

ولم تذهب من عتقها إلى الزمان بل إنما تذهب من عتقها إلى الكرم كما يقال فرس عتيق يراد به كريم. فما لحقته خواص الكرم فهو عتيق في أي دهر طبع. والطرف الأبعد من العتيق هو ضده في المعنى أعني ما عدم خواص العتيق فلذلك سمي بضد اسمه أعني محدث وان كان قد طبع قبل زمن عاد. وأما الآخذة بعض خواص العتيق وحارمة بعض خواصه فهي التي وجد فيها بعض خواص المحدث فسميت أيضا باسم متوسط بين الاسمين فقيل ليس بعتيق ولا محدث وان كان متقدم الزمان أو حديثه؛ فاختص الصياقلة لها اسم لا عتيق في بعضها ولا محدث في بعضها.

Three kinds of "antique" or quality swords:

“The antique are divided into three kinds. The first and best in quality of all is the Yemenite; the second is the Qal`i قلعي [5]; and the third is the Indian.”

فالعتيق ينقسم ثلاثة أقسام أولها وأجودها اليماني ثم ثانيها القلعي ثم ثالثها الهندي.

Swords forged from imported steel:

Some swords were called non-native غير مولّد. They were forged from imported steel. Some Khurasani swords for example were forged from steel imported from Sarandib; and this is the case in several other cities.

Swords forged from local iron:

“As for those native swords مولّدة, they fall into five kinds. Of these are the Khurasani, the iron which is produced and forged in Khurasan; the Basriyya, the iron of which is produced and forged at Basra; the Damascene, the iron of which is produced and forged at Damascus; the Egyptian, which is forged in Egypt. Swords in this category may be forged in other places like those of Baghdad, of Kufa, and a few other places, but are not attributed to such places because of their scarcity. These are all the types of swords which are made from manufactured iron, I mean from steel.”

وأما المولدة فتنقسم خمسة أقسام. منها الخراسانية وهي ما عمل حديده وطبع بخراسان. ومنها البصرية وهي ما عمل حديده وطبع بالبصرة. ومنها الدمشقية وهي ما عمل حديده وطبع بدمشق قديما. ومنها المصرية وهي ما طبع بمصر. وقد يطبع في مواضع غير هذه كالبغدادية والكوفية وغير ذلك من المواضع القليلة ولا تنسب اليها لقلتها. فهذه جميع أنواع السيوف المذكورة من الحديد المعمول أعني الفولاذ.

3. Al-Biruni on Damascus Crucible Steel

The next passage is from Kitab al-Jamahir fi ma`rifat al-jawahir الجماهر في معرفة الجواهر (A Compendium of Mineralogy( written by the celebrated savant, Abu al-Rayhan al-Biruni (973 -1048). Two main manuscripts were consulted. The first is Ms. Topkapi 2047 from Istanbul, and the other is Ms. Casiri 905 from the Escorial. Similarly, the book printed in Hyderabad was also consulted (Kitab al-Jamahir, edited by E. Krenkow, Hyderabad, 1936/37). Al-Biruni says:

“Mazyad b.`Ali, the Damascene blacksmith, wrote a book describing swords that were specified in al-Kindi's treatise. He commenced by dealing with the steel composition and the construction of the furnace (kur) as weIl as with the construction and design of crucibles, the description of (the varieties) of clay, and how to distinguish between them. Then he instructed that in each crucible five ratls of horseshoes and their nails should be placed, which are made of narmahin, as well as a weight of ten dirhams each of rusukhtaj روسختج , golden marcasite stone المرقشيشا الذهبي and brittle magnesia. The crucibles are plastered with clay and placed inside the furnace (kur). They are filled with charcoal and they (the crucibles) are blown upon with rumi bellows. each having two operators, until it (the iron) melts and whirls. Bundles صررare added containing ihlilaj (myrobalan), pomegranate rinds, salt (used in) dough, and oyster shells أصداف اللؤلؤ , lit. pearl shells, in equal portions, and crushed, each bundle weighing forty dirhams. One (bundle) is thrown into each crucible; then it (the crucible) is blown upon violently for an hour. Next, they (the crucibles) are left to cool, and the eggs are taken from the crucibles.”

ولمزبد بن علي الحداد الدمشقي كتاب في وصف السيوف الني اشتملت رسالة الكندي على أوصافها. ابتدأ العمل بنصاب الفولاذ وصنعة الكور وعمل البواطق ورسومها وصنعة أطيانها ثم أمر أن يجعل في كل بوطفة خمسة أرطال من نعال الدواب ومساميرها المعمولة من النرماهن ومن كل واحد من الروسختج والمرقشيشا الذهباني ولمغنيسا اشة وزن عشرة دراهم ويطين ابواطق وتودع الكور تملأ فحما ويفخ عليها بالمنافخ لرومية كل منفاخ برلين الى أن تذوب وتدور وقد أعد له صررا فيا اهليلج وقشر رمان وملح العجين وأصاف اللؤلؤ باسوية مجرشة في كل صرة أرعين درهما يلقى في كل بوطفة واحدة. ثم ينفخ علها نفخا شديدا بلا رحمة ثم تترك حتى تبرد وتخرج البيضات عن البواطق.

4. Al-Jildaki (commenting on Jabir ibn Hayyan) Discusses Pig Iron and Cast Steel

lt was found that Ms. no. 4121 of the Chester Beatty Library, contains a part of Kitab al-Hadid (The Book of lron) of Jabir ibn Hayyan, that is given in the course of a commentary by al-Jildaki (fi. c. 1339 -42). The following text from this Ms. is of great significance for the history of metallurgy:

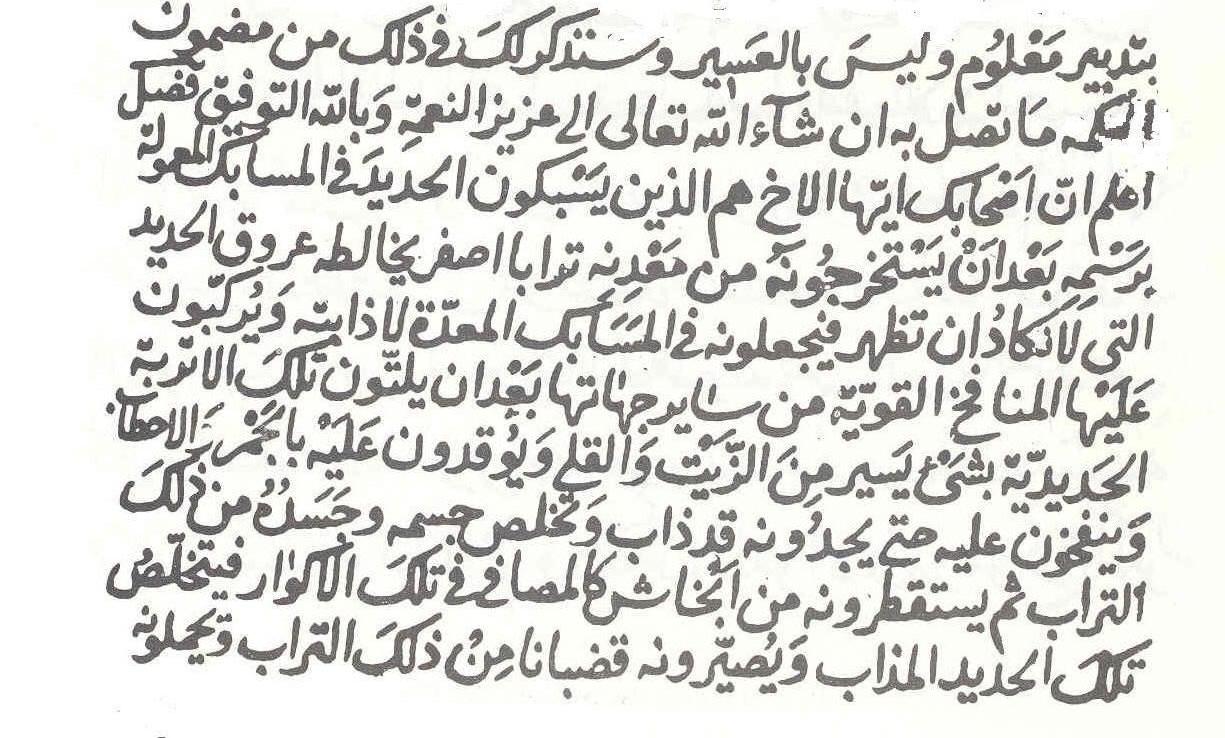

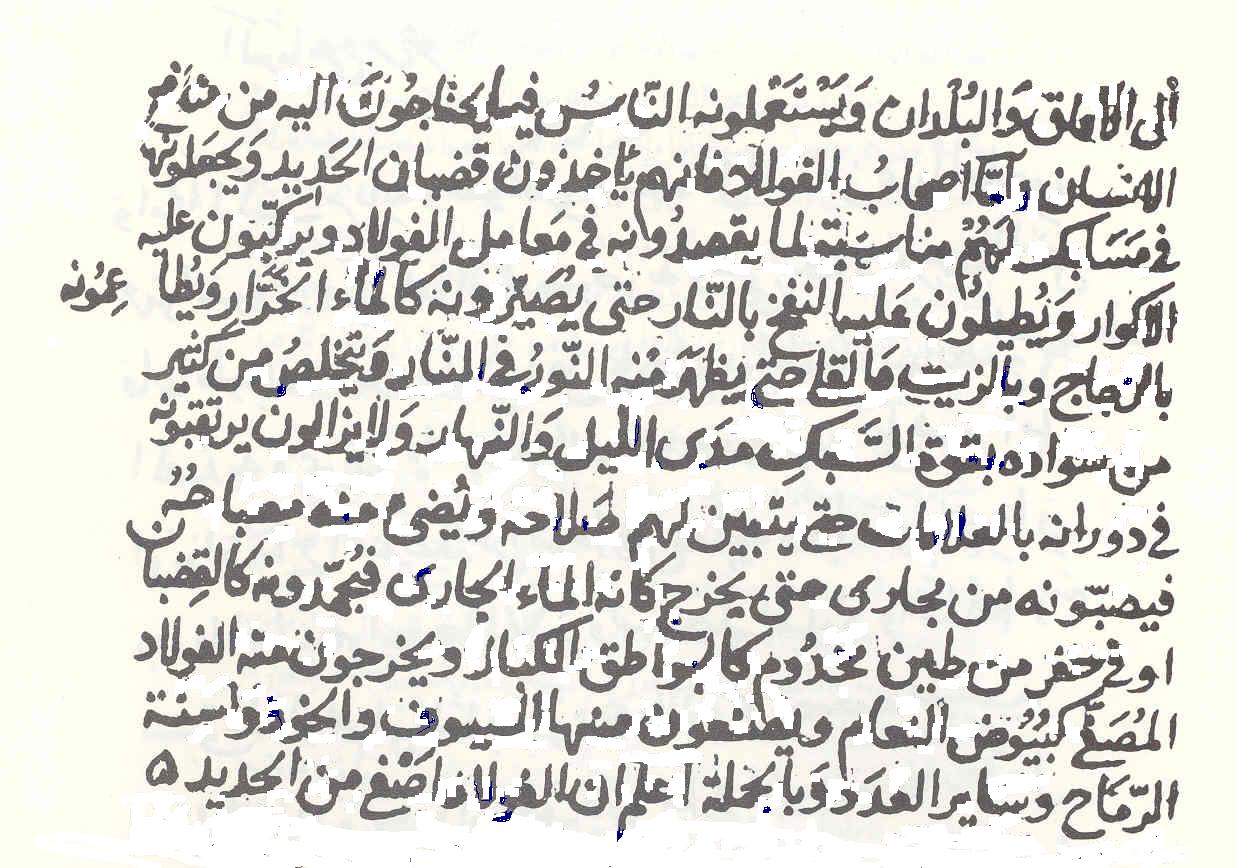

“Chapter: Learn, brother, that it is your comrades who found (from founding, melt metal يسكبون) iron in foundries (especially) made for that purpose after they have extracted it (the ore) from its mine as yellow earth intermingled with barely visible veins of iron. They place it in founding furnaces designed for smelting it. They install powerful bellows on all sides of them after having kneaded (يلتّون) a little oil and alkali into the ore. Then fire is applied to it (the ore), together with cinders (الجمر) and wood. They blow upon it until it is molten, and its entire substance جسمه وجسده is rid of that earth. Next, they cause it to drop through holes like (those of) strainers, (made in) the furnaces أكوار so that the molten iron is separated, and is made into bars from that soil. Then they transport it to far lands and countries. People use it for making utilitarian things of which they have need.

As for the steel workers, they take the iron bars and put them into founding-ovens مسابك which they have, suited to their objectives, in the steel works. They install firing equipment أكوار into them (the ovens) and blow fire upon it (the iron) for a long while until it becomes like gurgling water. They nourish it with glass, oil, and alkali until light appears from it in the fire and it is purified of much of its blackness by intensive founding, night and day. They keep watching while it whirls for indications until they are sure of its suitability, and its lamp emits light; Thereupon, they pour it out through channels so that it cornes out like running water. Then, they allow it to solidify in the shape of bars or in holes made of clay fashioned like large crucibles. They take out of them refined steel in the shape of ostrich eggs, and they make swords from it and helmets, lance heads, and all tools.” (see Arabic text below)

From these two descriptions it seems safe to state that the first process describes the production of pig iron (or cast iron), and that the second one describes the production of cast steel from pig iron.

5. lron Foundries in Damascus in the Twelfth and Thirteenth Centuries

Reference to iron foundries in Damascus in medieval times can be found in Arabic literature. Thus, in the book $ubh al-a`sha (Cairo: Ministry of Culture) by al-Qalqashandi (d. 1418), when discussing government departments in Damascus during the Ayyubid dynasty (1171-1250), the foIlowing statement occurs (vol. 4, p. 188):

“Of these are several smaIl military departments شدود such as the department of foundries شدّ المسابك for iron, copper, glass, and others.”

ومنها ....شدود صغار متعددة كشد المسابك من الحديد والنحاس والزجاج وغير ذلك.

Then, (on p. 190), al-Qalqashandi speaks about departments of the civil service in Damascus and says:

“Of these is the civil department of foundries نظر المسابك and the executive in charge of this department is the counterpart of the officer in charge of the military department of foundries شدّ المسابك who was mentioned above when dealing with military officers (men of the sword). “

The History of Damascus City ناريخ مدينة دمشق (Damascus: Arab Academy of Science,1954) by Abu al-Qasim `Ali ibn al-Hasan, known as Ibn `Asakir (d.1177), mentions (vol. 2, p. 58) the sites of iron foundries in Damascus.

6. Distinction between lndian and Damascus Steels in Arabic Literature

Zayn al-Din al-Dimashqi al-Jawbari(d.1232) wrote his book A Selective Book on Revealing Secrets المختار في كشف الاسرار ( printed Damascus, 1302 H) as a guidebook on how to discover cheating methods adopted by various trades and crafts. Chapter eight is on "revealing secrets of manufacturers of arms ". The following passage occurs (p. 61):

“They have a prescription for a (good) cutting sword: Indian steel or Damascus steel is taken and a sword is made of these steels which is strong (thick) in the middle and thin at the edges, with evenness such that no place is stronger than the other. Then, if it is heat-treated with the above-mentioned water, nothing can oppose it.”

ولهم صفة سيف قاطع: يؤخذ فولاذ هندي أو دمشقي فيعمل منه سيف قوي الوسط رقيق الجوانب متساويا لا يكون موضع أقوى من موضع ثم يسقى من الماء المتقدم ذكره سابقا فانه لا يقف قدامه شيء .

The passage below shows that the term "Damascus steel" was current during the fourteenth century. The quotation is from a manual on quality control by Dia' al-Din Muhammad al-Qurashi, known as Ibn al- Uhkuwwa, (d. 1329). The book is Ma`alim al-qurba fi ahkam a-hisba معالم القربة في أحكام الحسبة ( ed. Reuben Levy, Cambridge, 1938; repr. Baghdad, Muthanna), p. 224:

“An honest and trustworthy (individual) from among them (the artificers) is chosen (as inspector). He prevents (them) from mixing steel needIes with (those made of) armahan (soft iron, narmahin) for, when sharpened, they may be taken for those made from Damascus steel. Therefore each quality should be separate from the other, and he should take an oath from the artisans to follow these regulations. ”

يعرف عليهم رجلا ثقة أميتا من أهل صناعتهم يمنعهم أن يخلطوا الإبر الفولاذية مع الارمهان لأنها إذا سنت جاز أن تختلط بالفولاذ الدمشقي بل يكون ك نف منا على حدته يحلف الصناع عى ذلك.

7. The Firind or the "Damask" Pattern on Blades

All Islamic swords that were made from "Damascus steel" or from steels of similar quality showed the peculiar pattern that was referred to in Arabic literature as firind or "jawhar" فرند ، جوهر. The processes of producing steels in crucibles were practiced in Islamic lands mostly from native iron ores as we have shown above.

From al-Kindï's treatise, we learn that the "Damask" pattern or Firind الفرند or jawhar الجوهر is found in all manufactured steels. According to him, swords made from natural steels (non-manufactured, Shaburqan) have no pattern or "firind". When speaking about the firind of swords made from natural steel, al-Kindï states:

“These swords show no firind when treated with tarh [6] طرحor when treated otherwise, and aIl their iron is one colour.”

وهذه السيوف لا فرند لها في طرح ولا غيره وحديدها كله لون واحد

On the other band, aIl swords made from manufactured steel show the "firind" in varions degrees. Al-Kindi describes the "firind" or pattern of all types of manufactured steels and of swords produced in various localities in Islamic lands, and of Indian steel.

Al-Biruni in his above mentioned book (al-jamahir) gives a very interesting interpretation of the cause behind the formation of the firind or pattern in steels. It is due, in his opinion, to the incomplete mixing of two components of steel in the crucible: soft iron (narmahin) and its water (dus دوص):

"As to (iron) which is made from narmahin and its water which flows before it when it gets rid (of its impurities), it is caIled fuladh فولاذ (steel).

وأما المركب من النرماهن ومن مائه وهو الذي يسبقه الى الجريان عند التخليص فهو الفولاذ

Then he states:

“Fuladh (steel) in its composition is of two types. Either all that is in the crucible, narmahin and its water, is melted equally so that they become united in the mixing operation and no component can be differentiated or seen independently, and such steel is suitable for files and similar tools (and one may imagine that shaburqan is of such type and of a natural quality suited to hardening); or the degree of melting of the contents of the crucible varies, and thus the intermixing between both components is not complete, and the two components are shifted يتجاوز and thus each of their two colours (components) can be seen by the naked eye and it is called firind.” [7]

وحال الفولاذ في تركيبه على قسمين اما أن يذاب ما في البوطقة من النرماهن ومائه ذوبا سواء يتحدان به فلا يستبين أحدهما من الاخر ويستصلح للمبارد وأمثالها ، ومنه يسبق الى الوهم أن الشابورقان من هذا النوع وبصنعة طبيعية تقبل لها السقي؛ واما أن يخلف ذوب ما في البوطقة فلا يكمل الامتزاج بينهما بل يتجاوز اجزاؤهما فيرى كل جزء من لونيهما على حدة عيانا ويسمى فرندا.

AI-Biruni gives his definition of the two components of steel (which give rise to the firind) at the very beginning of the chapter on iron and he states:

“Narmahin is divided ...into two types. One is (narmahin) itself, and the other is its water which flows from it when it is melted and extracted from stones, and it is called dus دوص, in Persian it is called astah, and in the area of Zabilstan, ru رو, because of its speed of flow and because it overtakes iron when it is flowing. It is solid, white, and tends to be silvery.”

ثم ينقسم النرماهن ... الى ضربين أحدهما هو والاخر ماؤه السائل منه وقت الاذابة والتخليص من الحجارة ويسمى دوصا وبالفارسية استه وبنواحي زابلستان رو لسرعة خروجه وسيقه الحديد فب الجريان. وهو صلب أبيض يضرب الى الفضية.

Al-Biruni’s interpretation of the cause of the firind or pattern in Damascus steel is reminiscent of the modern interpretation of modern historians of metallurgy who were studying the secret of Damascus steel for the last two centuries.[8]

8. Iron Mines in Lebanon and Anti-Lebanon Ranges

The Geographer, Shams al-Din Abu `Abd Allah al-Maqdisi (also known as al-Muqaddasi, d. c. 1000), in Ahsan al-taqasim fi ma`rifat al-aqalim أحسن التقاسيم في معرفة الأقاليم (Leiden: Brill, 1906; repr. Baghdad, Muthanna), p. 184, when speaking about iqlim al-Sham (i. e. Syria) states that there were iron mines in the mountains of Beirut.

وبه معدن الحديد في جبال بيروت.

In like manner, al-Idrisi (d. c. 1160) in Nuzhat al-Mushtaq fi Ikhtiraq al-Afaq نزهة المشتاق في اختراق الافاق (see Eilhard Wiedemann, Aufsötze zur arabischen Wissenschaftsgeschichte, vol. 1, p. 740) reports that iron ore in large quantities was being mined in the vicinity of Beirut and transported to all parts of Syria.

The famous travel account, Rihlat Ibn Battuta رحلة ابن بطوطة (Beirut, Sadir, 1964), contains a remark by the author (p.62) to the effect that when he stopped over in Beirut in 1355, iron was being exported from there to Egypt:

ثم سرنا الى مدينة بيروت ... ويجلب منها الى ديار مصر الفواكه والجديد

Dawud Ibn `Umar al-Antaki (d. 1599) in his Tadhkira تذكرة داود الانطاكي (Cairo, n.d., p. 111) defines iron and describes the manufacture of steel from soft (female) iron in crucibles. He states that iron originates from Sham (i. e. greater Syria), Persia, and Veniceز

ويتولد باشام وفارس والبندقية

In the eighteenth century (between 1792 and 1798), the German traveller, U. I. Seetzen, in his Reisen (Berlin, 1854), Bd, 1, pp. 145, 188-191, reported that the ferrous industry in the Lebanese mountains was still flourishing. Operations involving mining, smelting, and the fabrication of steel implements were in full swing.

In the nineteenth century, W. M. Thomson, who lived in Syria, refers in his book The Land and the Book (London, 1886) to iron in the Lebanese mountains and to iron ore mining and smelting, which operations were still going on in about 1834.

In 1921, I. M. Toll wrote a paper on the Mineral Resources of Syria (Engineering and Mining Journal, vol. 112, 1921, p. 846) with a map showing the iron ore deposits. He describes the quality of iron ores and the locations of iron ore mining which was still going on in some localities. He states, however, that smelting of iron in the mountains of Lebanon came to an end in about 1870 due to scarcity of wood and fuel and the low price of imported iron.

9. Concluding Remarks

The selections presented above represent only a small portion of the Arabic sources bearing on the history of steel technology. Even so, they raise the question of how it came to be generally accepted that the role of Damascus was that of a commercial distribution center only.

The answer seems to be somewhat as follows. As the industrial revolution got underway early in the nineteenth century, European steel makers sought to emulate the quality of Damascus blades and that of the "wootz" steel then being imported into Britain from India. It was natural that their investigations should focus upon regions where the techniques were then known to be actively practiced, especially India. Thus, Syria and other Islamic lands came to be ignored. The literature on the subject of Damascus steel is considerable. The interested reader will find much of it referred to in Cyril S. Smith's A History of Metallography (Chicago: The University of Chicago Press, 1960). Curiously enough, Smith makes no mention of the work of Eilhard Wiedemann, who in Beitrage XXIII and XXV of Aufsätze zur arabischen Wissenschaftsgeschichte (Hildesheim - New York: Georg Olms Verlag, 1970) gives German translation of numerous passages from Arabic material.

Note: All bibliographies are given within the text of the article

[1] This paper is an edited version of our article « Iron and Steel Technology in Medieval Arabic Sources », Journal for the History of Arabic Science, Vol. 2, Number 1, May 1978, Aleppo, pp. 31-43.

[2] These passages are based mainly on Ms. Ayasofya 4832, folios. 170-172. See also: `Abd al-Rahman Zakï, al-Suyuf wa Ajnasuha", an edited Arabic text, Faculty of Arts Journal, vol. 14, part 2, Cairo, 1952; Hammer-Purgstall, Baron de, "Sur les Lames des Orientaux", Journal Asiatique, Ve Serie, tome III, pp. 66 -80, Paris, 1854.

[3] Firind is the pattern that characterizes Damascus steel swords.

[4] `Ad - is an ancient tribe, frequently mentioned in the Qur’an. It was said to have been a mighty nation that lived immediately after the time of Noah.

[5] Qal`i : This steel is referred to "Qal`a", a place wbich is difficult to locate. Some sources of Arabic literature assume that it was in Arabia; other sources assume that it was in Syria; while others assume it was in North India, or in the Indian Ocean, and so on.

[6] Tarh referrs here to the drug (mixture of materials) that is used to treat the surfaces of swords to show their firind or pattern.

[7] For the modern interpretation of the cause of the firind see Cyril S. Smith, A History of Metallugraphy, Chicago, 1960. pp.14-24

MS. Chester Beatty 4121, folios 1v -2r

Copyright Information

All Articles and Brief Notes are written by Ahmad Y. al-Hassan unless where indicated otherwise.

The design of this website does not belong to Ahmad Y. al-Hassan, the design was based on common webdesign elements.

All published material are the copyright of the author (unless stated otherwise) and may not be published or reproduced in part or in whole without the express written permission of the author.