History of Science and Technology in Islam

Description of Soap Making[1]

From a Thirteenth Century Treatise by King Al- Muzaffar Yusuf ibn `Umar ibn `Ali ibn Rasul (d. 1294)[2]

In Antiquity, though mixtures containing soap were known and used in Mesopotamia, soap as such was unknown, but several detergents were in use.[3] The classical world did not have better detergents, and bran, pumice-stone, natron, vegetable alkali and the like were used. Later on, Pliny described a soft kind of soap made by the Gauls but historians think that this was pomade made from un-saponified fat and alkali. [4]

In medieval times the soaps that were made in northern Europe by the action of wood-ash lyes on animal fats and fish-oils were soft soaps of unpleasant odour. They were used for cleaning textiles and clothes, and it is difficult to say whether it was widely used for personal washing. Personal cleansing by using hard soap was not a common practice in Europe and there is no reason to suppose much improvement in these matters before the middle of the eighteenth century.[5]

Syria was renowned for its hard soap, which was pleasant to use for toilet purposes. Archaeological excavations found soap works dating from the eighth century.[6] Geographers of the tenth century reported that Nabulus in Palestine was prominent in its soap exports.[7] Soap was manufactured in the other Mediterranean Arab-Islamic lands including Muslim Spain where olive oil was abundant. In 1200 AD Fez alone had in it 27 soap manufacturers.[8] In the thirteenth century, hard soap was imported by Europe from the Arab lands of the Mediterranean and was shipped across the Alps to northern Europe via Italy.[9]

No clear European description of how soap was made has survived from the mediaeval period. The earliest is contained in The Secrets of Master Alexis of Piedmont, written about 1547.[10]

In Arabic literature although we find short recipes in the early alchemical treatises of al-Razi yet until recently the only known detailed description was that of al-Antaki (seventeenth century)[11]. In this Brief Note we are presenting a newly discovered text from the thirteenth century describing soap making. It is given in Al-mukhtara` fi funun min al- suna` (Inventions from the Various Industrial Arts) [12] that was compiled by King al-Muzaffar Yusuf ibn `Umar ibn `Ali ibn Rasul (d. 694/1295) of Yemen. Since this description is for a Yemeni practice where olive oil is not produced, sesame oil is used instead.

Description of Soap Making

Take two thirds from alkali (al-qily} and one third of un-slaked lime (nura dhakar). Break the lime into small pieces the size of faufal [13]or chestnut. Take a mirkan [14](large vessel} of pottery and cut an outlet (manzil) at its bottom. And seal this outlet tightly with a rag. Take bricks and break them into small pieces, not quite small, and pack them inside the middle of the mirkan. Place on the broken bricks a piece of khsaf.[15] Throw on the khasafa the alkali and the un-slaked lime. And pour on them an amount of water equal to four or five times the submersion volume. The mirkan should be placed on a high position, and we place under the outlet another empty mirkan so that the liquid will flow into it. If there is no high place you will dig a cavity in the ground at a depth equal to that of the empty mirkan, and it is lowered down the cavity so that it is below the outlet. Leave it for one day and one night then open the outlet on the second day so that the filtered water of alkali and lime will pour into it. When all the liquid is emptied, return again and pour it above the alkali and lime and leave it for one day and one night. Open the outlet the next morning and empty the whole clear liquid. When the whole liquid ceases flowing divide it into two halves. Put one half aside. Pour [onto the remaining half] an equal amount of sesame oil (shiraj) and beat (agitate) the mixture strongly and repetitively with a wooden beater for one hour until it hardens and thickens. Leave it for the rest of the day and overnight if you are in a hurry, otherwise leave it for two or three days if you are not in a hurry because the longer it stays the better it ferments. Cool it down and put it in a copper cauldron and set under it a strong fire. Each time it thickens water it with the sharp water from the one half that was put aside as mentioned above. You will continue kindling the fire and watering with the sharp water until it becomes grainy and ripens. Continue beating (mixing) it so that it will not burn. Put it down and pour it into a mirkan (a large vessel) and beat it and water it little by little, then pour it again into the cauldron and place it on fire, let it be a strong fire, and whenever it tends to become dry, water it with the sharp water little by little while you are stirring so that it will not burn. Continue like this until the water is consumed and the soap is well cooked and its consistency becomes like that of the shoemakers glue, known as ashras. Make a milban (mould) from wood, similar to the milban of bricks, but larger. Spread a kham cloth {coarse cotton cloth) or a piece of khasf and place the milban (the mould) over it. Pour the soap into the milban. The purpose of the milban (the mould) is to prevent the soap from flowing until it thickens. Leave it for one night and one day until it solidifies. Then cut it with a knife as is usual. If you want the soap to be perfumed add to it, on the last cooking on fire, choice perfumes and saffron and whatever scents you like then pour it as above mentioned, if God wills.

[1]For more information on soap making see al-Hassan and Hill, Islamic Technology, an illustrated history, UNESCO and CUP, 1986, pp. 150-151. See also The Different Aspects of Islamic Culture, Science and Technology in Islam Civilization in Islam, Vol. 4, Part II.UNESCO, 2001, p. 73-74

[2] King Al- Muzaffar Yusuf ibn `Umar ibn `Ali ibn Rasul, was king of Yemen (1249-1295). He was the second of the Bani Rasul dynasty, several of whom were learned scholars who left important works on medicine, pharmacology, agriculture and technology. The author King al-Muzaffar was one of the learned kings and he patronized several scientists and artisans.

[3] Forbes, R. J., Studies in Ancient Technology, vol. III, Leiden, 1965, p.187.

[4] Partington, J. R., History of Greek Fire and Gunpowder, John Hopkins, 1999, p. 307

[5] Sherwood Taylor, F., A History of Industrial Chemistry, New York, 1957, pp. 132-133.

[6] Elisseeff, N, article ‘Qasr al- Hayr al- Sharqi, in Encyclopaedia of Islam Vol. IV, .New Edition, Brill, Leiden, p. 727b

[7] Al-Maqdisi, Ahsan al-Taqasim fi ma`rifat al-aqalim, ed. De Goeje, Brill, Leiden, 1906, offset reproduction by Qasim al-Rajab, Baghdad, n.d., p. 180

[8] Shatzmiller, M., Encyclopaedia of Islam , Vol. VII, New Edition, article ‘al-Muwahhidun’, Brill, Leiden, p.801b

[9] Sherwood Taylor, op. cit., pp. 132-133. See also Lopez, Robert S., and Irving WW. Raymond, Medieval Trade in the Mediterranean World, Columbia University Press, New York, 2001, p. 113.

[10] Sherwood Taylor, op. cit., p. 133

[11] al-Hassan and Hill, op. cit., pp. 150-151

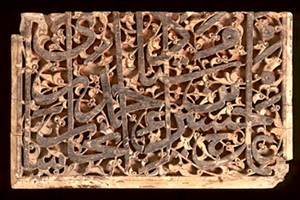

[12] This treatise was edited and published byMuhammad `Ali Salhiyyeh, Kuwait, 1998, the soap process is described on pp. 198-200. There are three manuscripts for this treatise, one of them is in Cairo, one in Milan, and one in Hayder Abad. We reproduce with this note a copy of the folios describing soap making from MS No.C22 at the Ambroziana Library in Milan.

[13] Areca Catechu or betel nut. Siggel, Alfred, Arabisch-Deutsches Worterbuch der Stoffe,, Berlin, 1950, p.57 .

[14] Lane, Edward William, Madd al-Qamus, Arabic-English Lexicon, London, 1867, Reproduced by Libraire du Liban, Beirut, 1997, part 3, p. 1149

[15] Khasaf , khsafa, piece of matting made from palm leaves woven together. Khsafa means also a very thick kind of cloth. Lane, op. cit., part 2, p. 750

Copyright Information

All Articles and Brief Notes are written by Ahmad Y. al-Hassan unless where indicated otherwise.

The design of this website does not belong to Ahmad Y. al-Hassan, the design was based on common webdesign elements.

All published material are the copyright of the author (unless stated otherwise) and may not be published or reproduced in part or in whole without the express written permission of the author.